INFINITY Low Or High Speed Train Weighing System

INFINITY ‘LS’ - Low Speed weighing up to 15km/h:

INFINITY ‘HS’ - High Speed weighing up to 80km/h:

BENEFITS:

- Actual reliable proven load cell based system

- No rail cutting, welding or grinding required

- Minimal installation / repair track down time

- User friendly

- Approx. 30 mins to change parts

- Temperature compensated

INFINITY TECHNICAL DATA:

- LS (Low Speed) = 0.1 To 15KM/H (0.06 To 9MPH)

- HS (High Speed) = 0.1 To 80KM/H (0.06 To 50MPH)

INFINITY in transport boxes

Assembled INFINITY

INFINITY in transport boxes

INFINITY under the track

Installation of INFINITY 'LS' weighing system in curved track *(up to 5km/h)

MTW STATIC or IN MOTION MOBILE TRAIN WEIGHER

The MTW design incorporates a chassis arrangement with an integrated loadcell and this design means weight is applied directly to the loadcell and not through the rail.

The advantage of weighing axle by axle is that there is no restriction with regards to wagon type. The MTW is factory pre-calibrated so that no transport of test weights are required.

CONSISTS OF (single base unit):

- 2 x loadcells

- 2 x scale main bodies

- 1 x set of shoes (to suit nominated rail type)

- 1 x set of spacer poles

- 1 x height measuring gauge

- 1 x weight indicator & printer housed in carry case

- 1 x set of height packers

- 1 x battery charger

- 1 x spanner

- 1 x cable set

- 1 x operation manual

FEATURES:

- User friendly

- Loadcell based system

- Four easy steps to install (2 men - approx 15 minutes)

- Transportable in the boot of a car, suv or train cabin

- Individual wheel weights can also be obtained

- Wheel, axle, bogie and vehicle weight

- Multiple MTW’s can be combined together

- Fits all recognised rail gauges

- Instant printout and / or download to PC

BENEFITS:

- Approx. 15 mins track downtime during installation

- No costly civil works required

- Battery operated or mains power

- Simple operation

FORCE 1 - The World's Toughest Axle Weigher

INSTALL IN 1 DAY! WEIGH A TRUCK IN 15 SECONDS!

SAVE TIME & MONEY by weighing on the go and eliminating the need for traditional weighbridges which consume valuable yard space, are expensive & can take approx. 1 week to install.

The unbeatable FORCE STATIC or IN MOTION truck scale is designed to endure the world’s most challenging of transport environments, whilst addressing high accuracy. Increase your production and overall profit by quickly measuring consistent accurate loads as well as addressing the maintenance risks associated with overloading. Note: A truck may be correct weight but the axles overloaded. FORCE 1 can identify this problem.Static/Dynamic Controller – PC Software

The FORCE 1 Transport system features a Trakblaze Static/Dynamic Controller with direct ethernet capabilities interfaced to your workplace PC, laptop or a handheld device.

The PC is preloaded with Trakblaze’s user-friendlyproven and reliable software.

The total truck weight is then derived from the summation of the individual axle loads and displayed on the PC interface and external remote LED display whilst also printed out for log books or archiving. Alternatively, for dusty or challenging environments the FORCE 1 controller can be upgraded to a rack/wall mounted rittal enclosure turnkey.

Whatever your workplace or challenging environment is, the FORCE 1 system and Trakblaze have the bespoke solutions to ensure your loads are weighed with unbeatable speed, reliability and accuracy.

BENEFITS:

- Unmatched Speeds up to approx. 10kph

- Unmatched Accuracies at approx. ± 0.05%

- User-friendly Software

- Latest Electronic Technology

- Robust Compact Design

- Minimal Civil Works Required

- IP-65 Rating

- Relocatable

FORCE 2 & 3 - Proven To Be The World's Toughest Mining Truck Scale

The range of FORCE portable and fixed mining dump truck scales are the ultimate in weighing technology for off road heavy haulage applications. Each system is designed to optimise accuracy and built to last! FORCE can be a fixed or portable mobile system made up of a combination of 2 or 4 individual weigh pads and measure the load on each wheel axle group and the total weight of a dump truck. The modern modular design enables the FORCE to be configured to weigh any make and model of mining haul truck.

In addition the FORCE series can even monitor your employees travel and productivity times (optional).

Features either a touch screen PC controller mounted in a weatherproof enclosure or a PC based rack system loaded with Trakblaze’s proven and reliable user friendly software. The total truck weight is then derived from the summation of the individual wheel and axle loads and displayed on the PC interface.

Load Sensors

Each hi-technology weigh pad incorporates multiple heavy duty “OIML approved” temperature compensated load cells. The strategic positioning of these sensors within the pad allows for off-center wheel loads to be measured accurately and with a safe overload sufficient to deal with the inertia and shock effects of a loaded mining truck braking on the weigh pad.

Accuracy

Accuracies of approx. ± 0.05 in static mode and ± 0.5% in dynamic (in-motion) mode (Gross Vehicle Mass). This is achievable dependent upon the site conditions and the operator.

Calibration

Each FORCE system is factory calibrated prior to shipment. We also offer an optional in-field calibration portable test press unit, which can be used at site by local service personnel.

TRUCKMATE - The Next Generation Portable Axle Weigher

Designed for durability in mind, TRUCKMATE features two high-quality weighing pads capable of handling up to 40 tonne per axle. Constructed from heavy-duty steel, these pads provide a non-slip surface for precise weight readings in any operating environment.

One of the key features of the TRUCKMATE Axle Vehicle Weighing Scale is its wireless connectivity, which allows for easy data transfer and real-time weight monitoring.

The system includes a compact and lightweight controller with a clear LCD display and printer in a robust carry case providing users with accurate weight readings.

Key features:

- Slimline

- Splash proof

- Load cell based with high static or weigh in-motion high accuracy

- OIML Standard Static accuracy

- Large weighing surface that can accommodate dual tyres

- Built-in cable protector to avoid error when cable is broken (wired version)

- Built-in anti-electromagnetic interference to make sure weighing results will not be influenced

- Built-in auto compensation system to compensate for weighing error on dual and tri-axle groups

TVS - Mining / Haul Truck Volumetric Scanner

Maximising Profits & Payloads.

Realtime Volumetric Scanning System for Mine Haul Trucks.

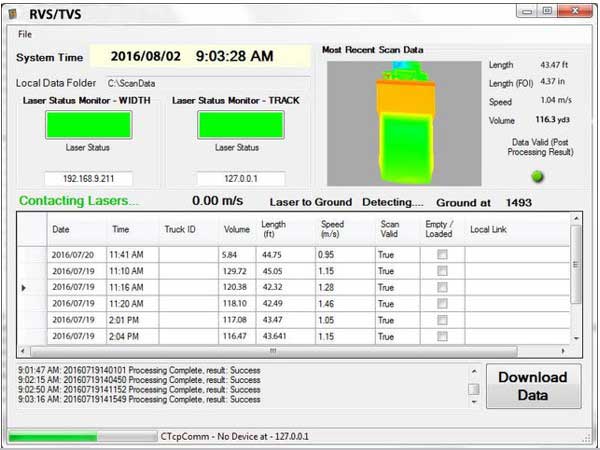

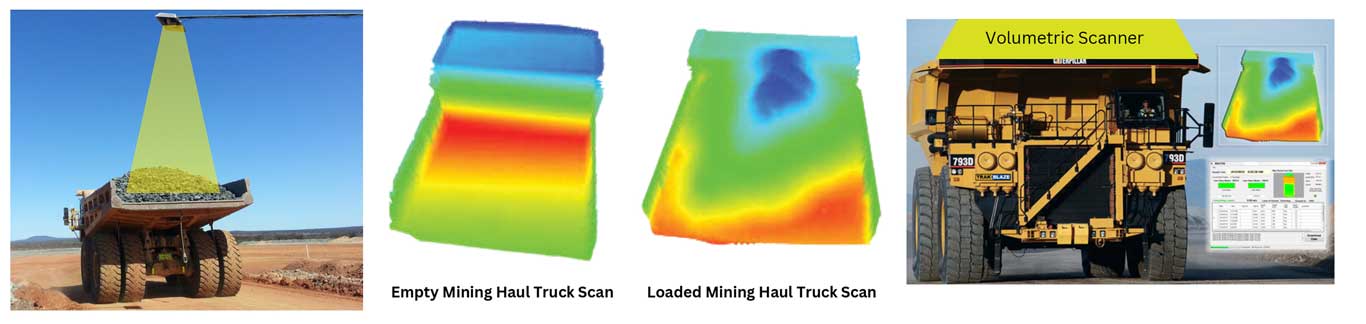

TVS is a non-contact volumetric measurement scanning system designed to measure loads of bulk loose solids & minerals in mining trucks.The TVS software has been developed specifically to allow direct acquisition of data from the intergrated laser scan head allowing for real-time monitoring of payloads.

System Description

Trucks or rail wagons are scanned by driving slowly below an elevated Scan Head. This is essentially a mounting platform for two scanning laser range finders which are referred as laser scanners. When a truck crosses below the Scan Head, it falls within the field of view of the laser scanners which perform thousands of distance measurements per second to obtain data.The scanner processes the distance data measured by the laser scanners as a truck passes below and constructs a composite 3D model or ‘surface profile’ in the software.

A vehicle is initially scanned empty and recorded into the system database as an empty vehicle profile (zero reference). Load volume is computed on subsequent scans by comparing each new loaded vehicle profile against the recorded empty profile.This involves aligning the empty and loaded vehicle profiles spatially in software and computing a load profile from then difference between them.

Software: