WEAR PROTECTION LINING

Rexline Premium Cold Lining Tanks

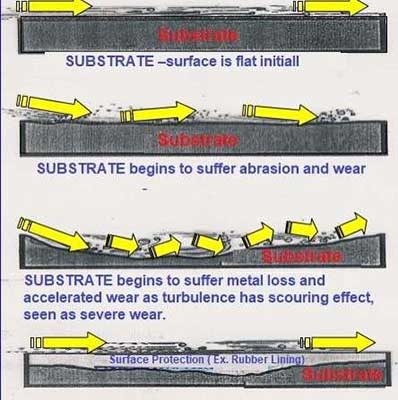

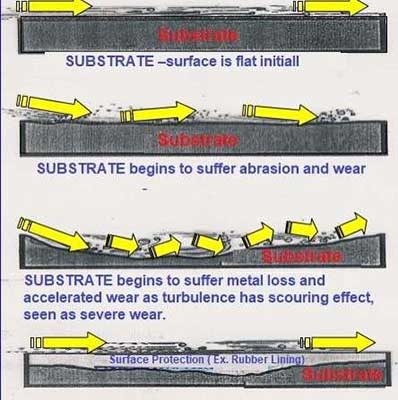

Wear & Abrasion

- Wear and Abrasion is the process of wearing down or rubbing away by means of friction

- Wear and Abrasion can also be found in wet and dry service conditions

- Excessive wear and abrasion results in substrate failure

Rubber Lining

Dependable & Long Term Protection For Plant Equipment Against Corrosion And Abrasion.

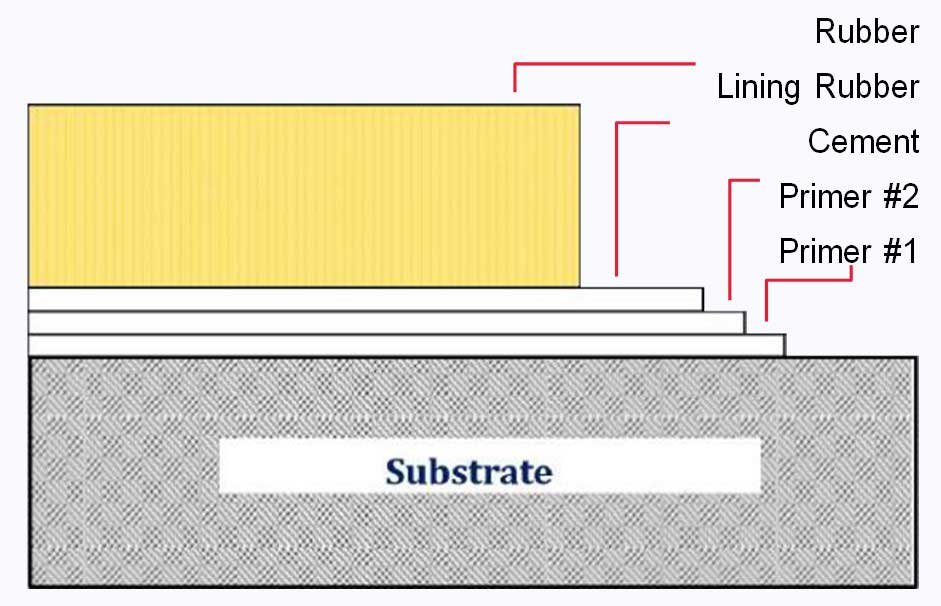

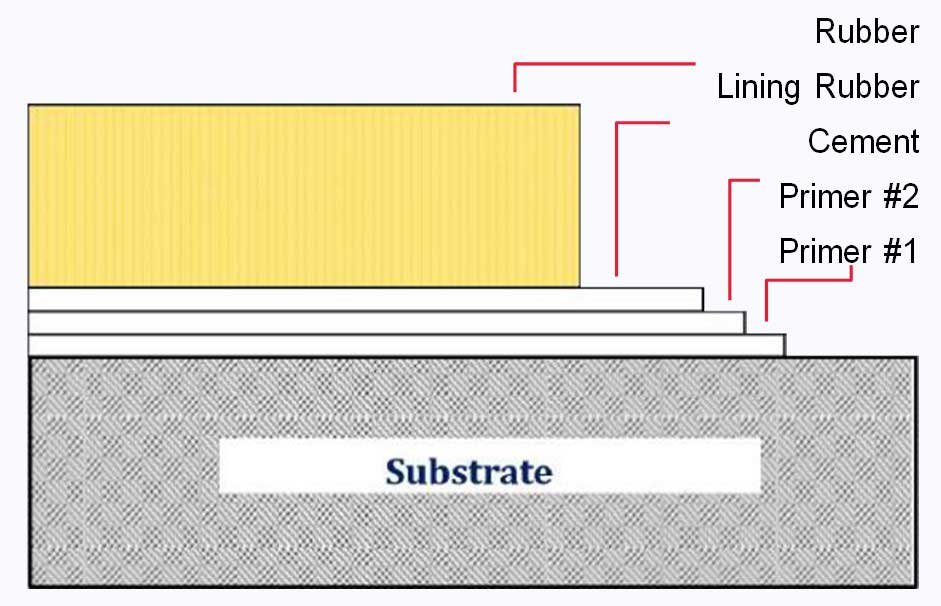

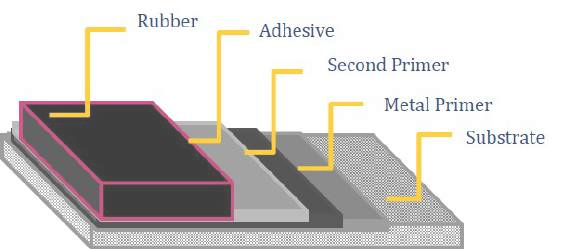

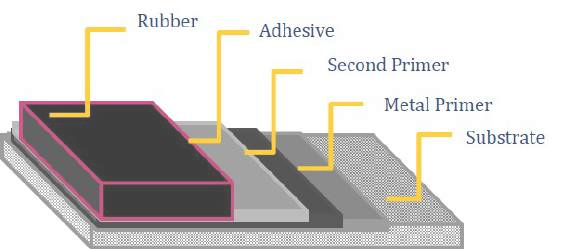

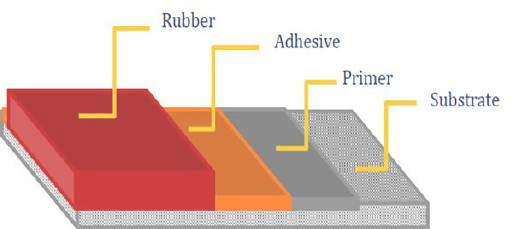

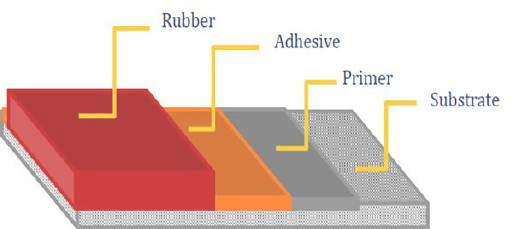

Configuration of Rubber Lining

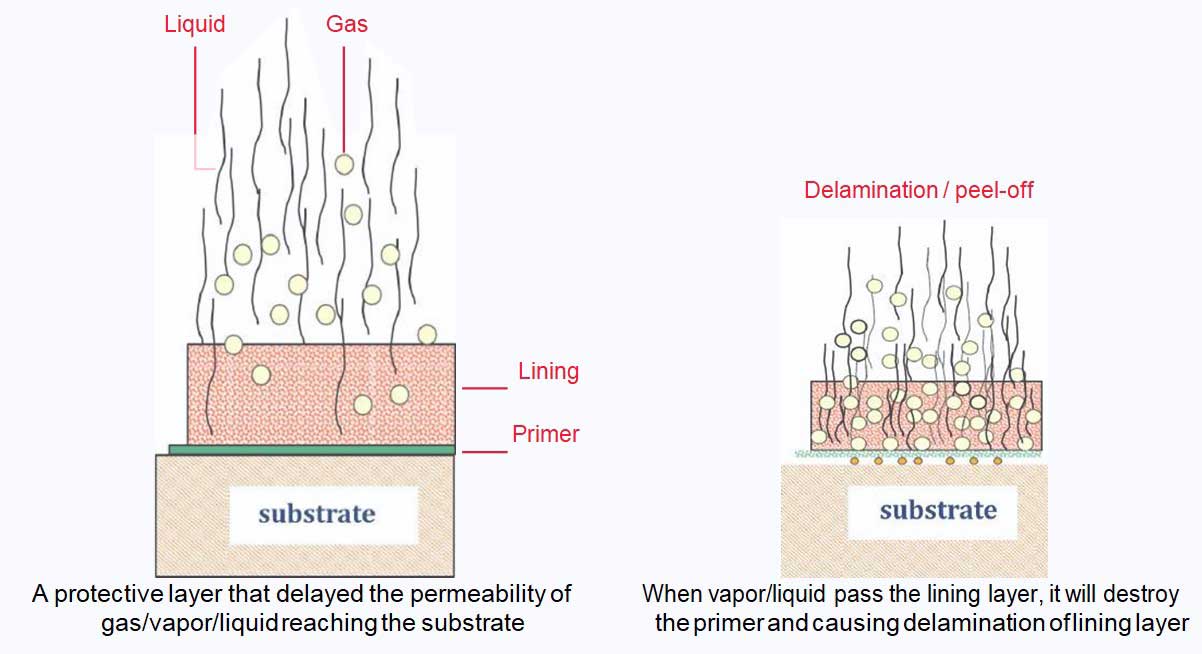

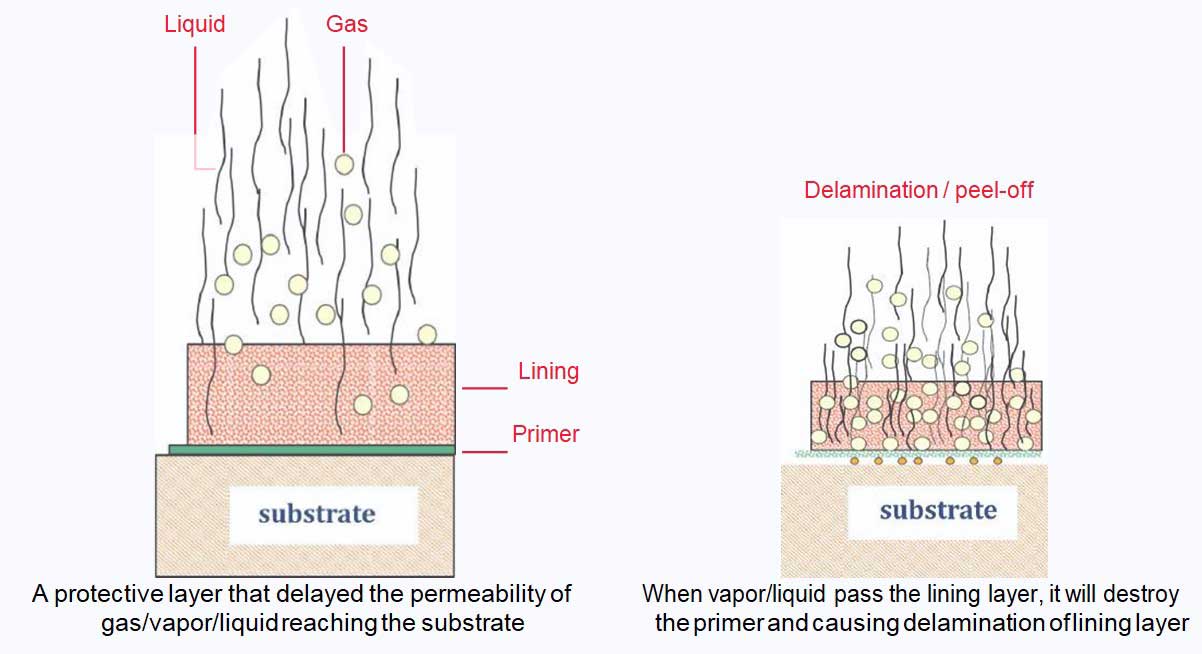

Corrosion Protective Lining

Specification of Rubber

When selecting rubber lining materials, the following physical properties shall be considered :

- Tensile strength

- Elongation at break

- Density

- Hardness

- Abrasion

- Rebound resilience

- Tear growth resistance

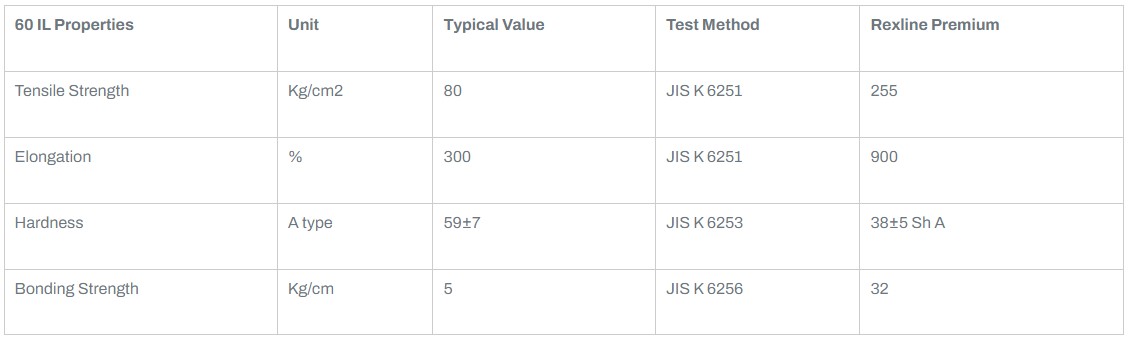

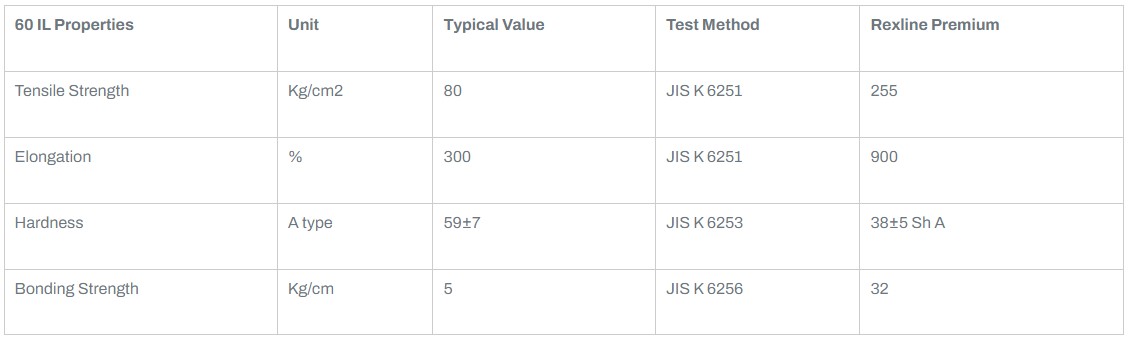

Sample of Rubber Specification

60 IL Properties | Unit | Typical Value | Test Method | Rexline Premium |

Tensile Strength | Kg/cm2 | 80 | JIS K 6251 | 255 |

Elongation | % | 300 | JIS K 6251 | 900 |

Hardness | A type | 59±7 | JIS K 6253 | 38±5 Sh A |

Bonding Strength | Kg/cm | 5 | JIS K 6256 | 32 |

Sample of Rubber Specification

Type of Rubber Lining

Type of Rubber Lining Based on Curing System

- Hot Lining System

- Cold Lining System

Type o Rubber Lining Based on Hardness

- Soft Rubber

- Hard Rubber/ Ebonite Rubber

Most Popular Type Material of Rubber Lining:

- Natural Rubber- NR has good physical properties such as abrasive, tensile strength, tear strength and elongation break. Other that NR has good chemical resistance.

- Butyl Rubber- Butyl rubber has Excellent chemical rubber, so butyl rubber suitable for chemical tank and other equipment with high concrentarion chemical.

- Chloroprene Rubber- Chloroprene rubber has excellent bonding, so the CR is commonly used for adhesive product. CR suitable for lining sea water equipment because CR has antibacterial sea water.

- Hard Rubber- Hard rubber is widely use as protective lining for highly corrosive substance at elevated temperature.

- Sand-hard (Soft-hard-soft)- The soft rubber outer layer against abrasion, when chemical permeate the soft rubber layer, it will be stopped by middle layer of hard rubber. The last layer of soft rubber form a strong bonding to the steel and also can take the thermal expansion of the tank.

Material & Application

Rubber Lining Application

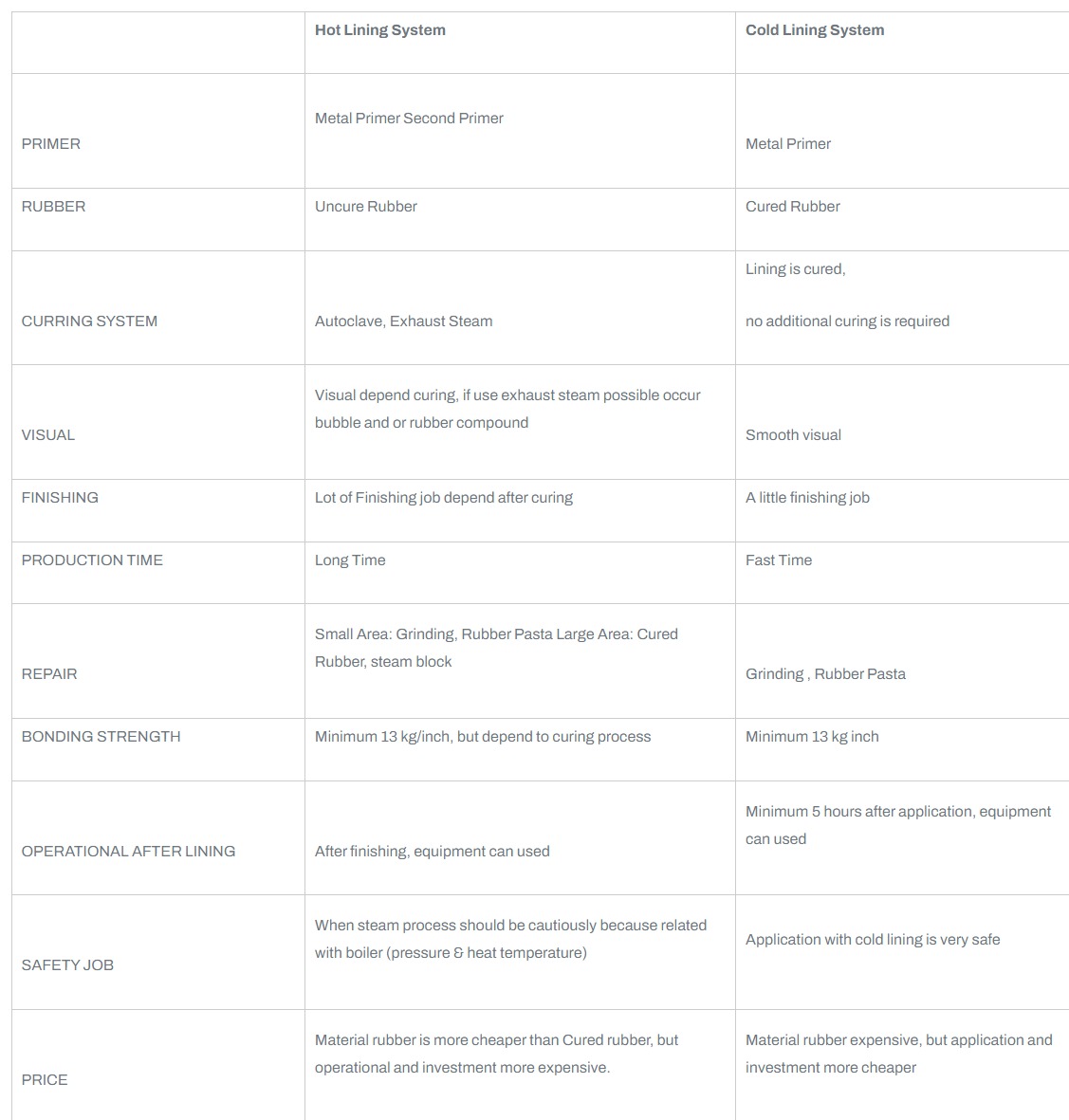

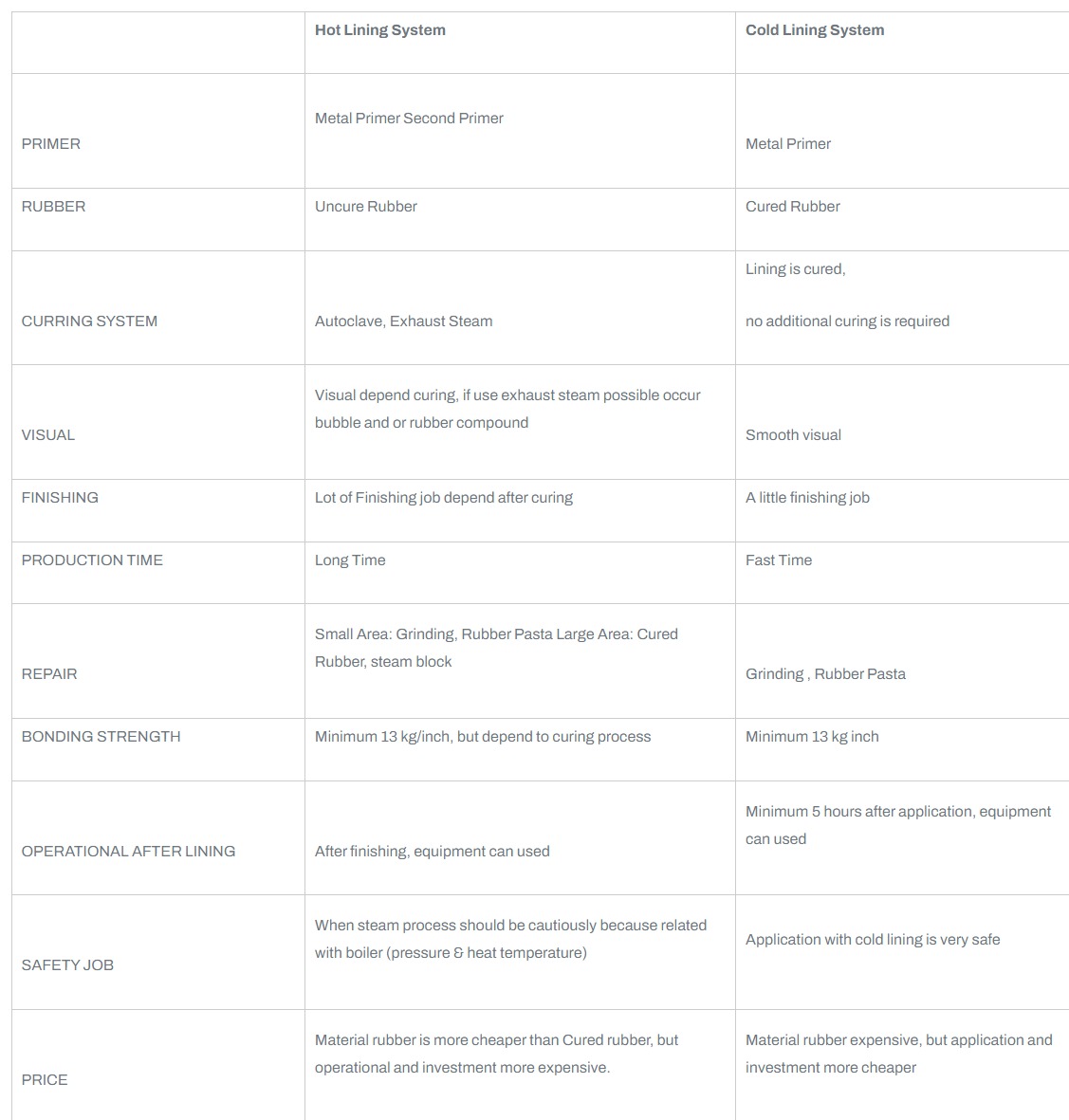

Comparison Curing Method

| Hot Lining System | Cold Lining System |

PRIMER | Metal Primer Second Primer |

Metal Primer |

RUBBER | Uncure Rubber | Cured Rubber |

CURRING SYSTEM |

Autoclave, Exhaust Steam | Lining is cured, no additional curing is required |

VISUAL | Visual depend curing, if use exhaust steam possible occur bubble and or rubber compound |

Smooth visual |

FINISHING | Lot of Finishing job depend after curing | A little finishing job |

PRODUCTION TIME | Long Time | Fast Time |

REPAIR | Small Area: Grinding, Rubber Pasta Large Area: Cured Rubber, steam block |

Grinding , Rubber Pasta |

BONDING STRENGTH | Minimum 13 kg/inch, but depend to curing process | Minimum 13 kg inch |

OPERATIONAL AFTER LINING |

After finishing, equipment can used | Minimum 5 hours after application, equipment can used |

SAFETY JOB | When steam process should be cautiously because related with boiler (pressure & heat temperature) | Application with cold lining is very safe |

PRICE | Material rubber is more cheaper than Cured rubber, but operational and investment more expensive. | Material rubber expensive, but application and investment more cheaper |

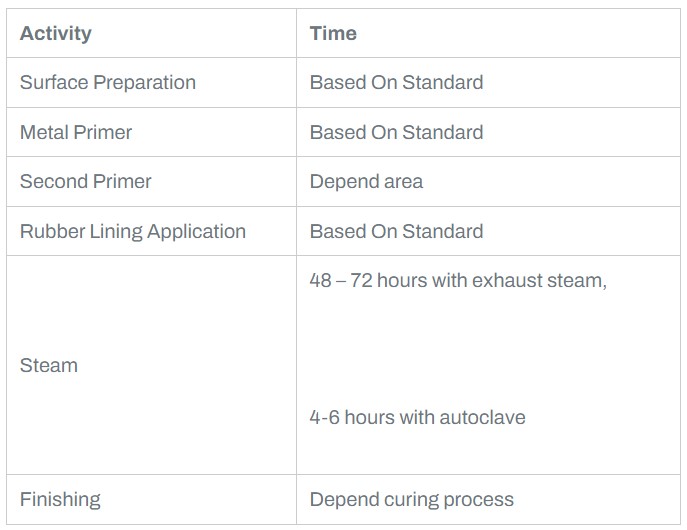

Production Time

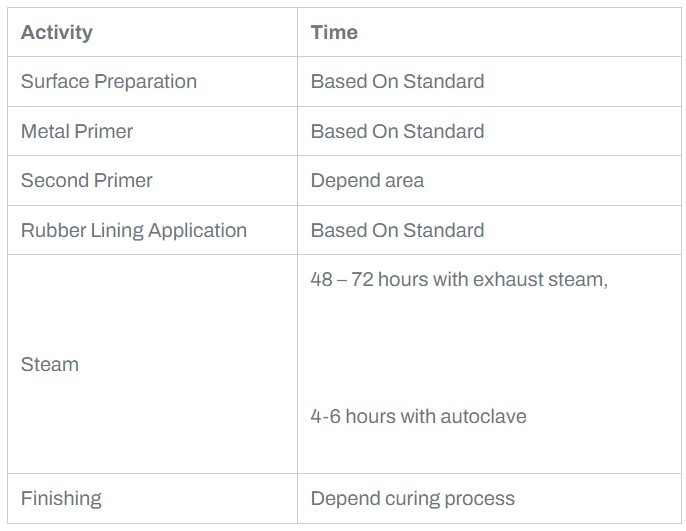

HOT LINING SYSTEM

| Activity | Time |

| Surface Preparation | Based On Standard |

| Metal Primer | Based On Standard |

| Second Primer | Depend area |

| Rubber Lining Application | Based On Standard |

| Steam | 48 – 72 hours with exhaust steam,

4-6 hours with autoclave |

| Finishing | Depend curing process |

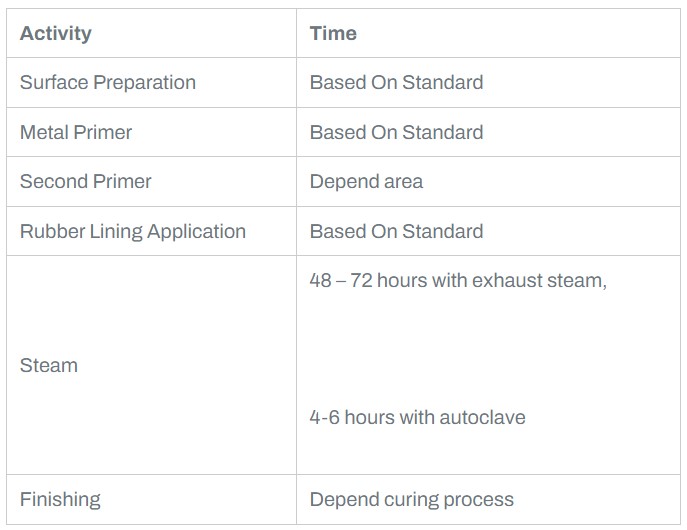

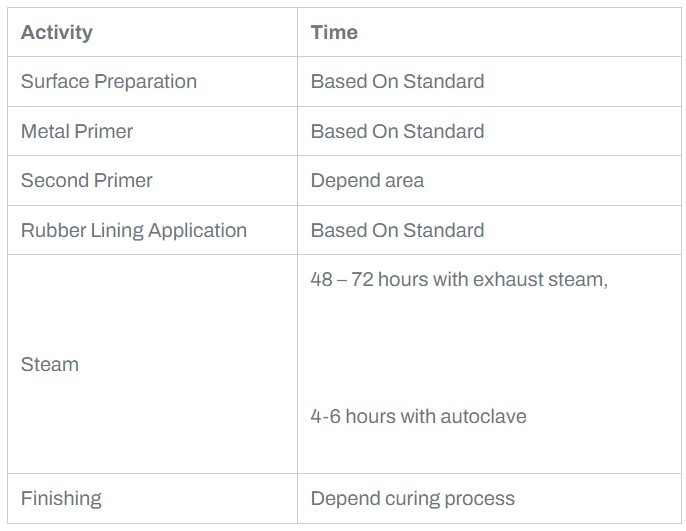

COLD LINING SYSTEM

| Activity | Time |

| Surface Preparation | Based On Standard |

| Metal Primer | Based On Standard |

| Second Primer | Depend area |

| Rubber Lining Application | Based On Standard |

| Steam | 48 – 72 hours with exhaust steam,

4-6 hours with autoclave |

| Finishing | Depend curing process |

HOT LINING SYSTEM

COLD LINING SYSTEM

Rubber Lining Inspection

HUMIDITY Standard

- Max RH 85%

- Min Diff Dew Point 3⁰C

- The conditions shall be monitored and recorded throughout the application (start from surface preparation till rubber lining application) to maintain bonding quality