Front End Engineering

Front End Engineering

Rxline Indonesia: Expertise in forming solid client alignments and studies.

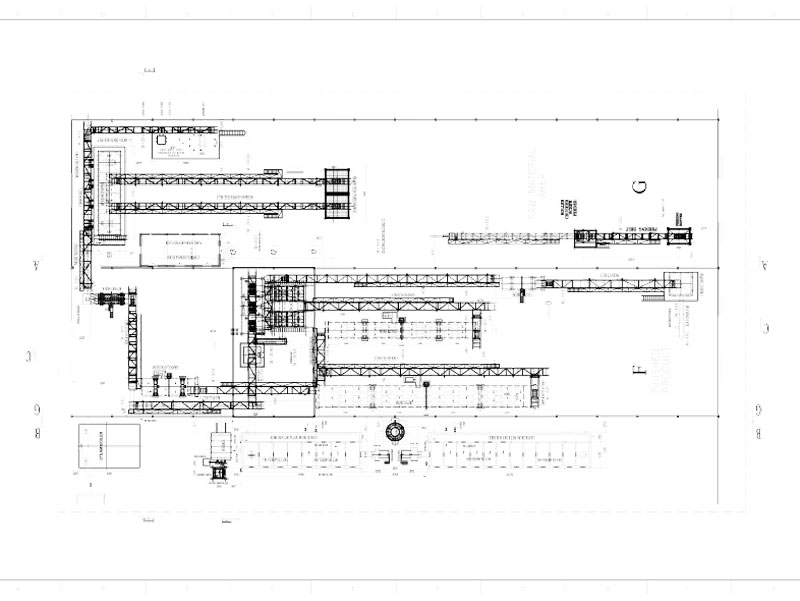

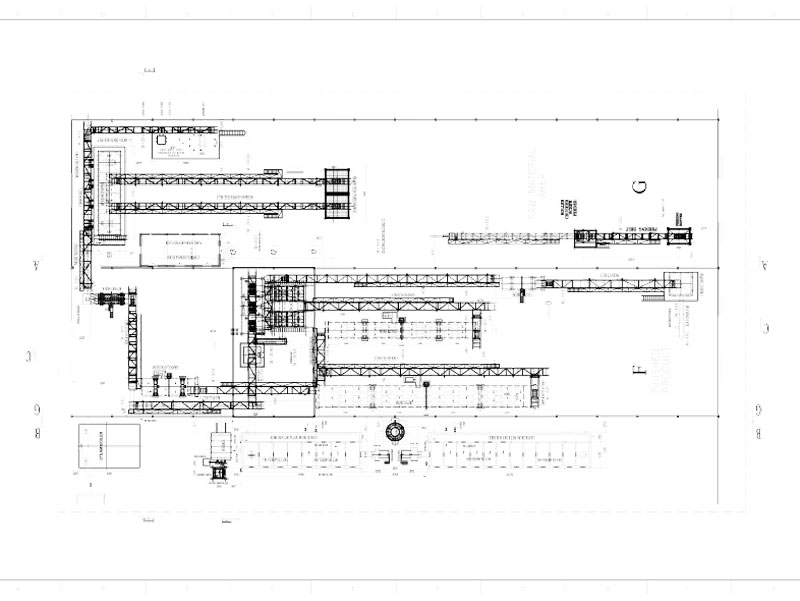

Engineering & Design

Engineering & Design

Vertically integrated capabilities: one-stop shop for design, sourcing, manufacturing.

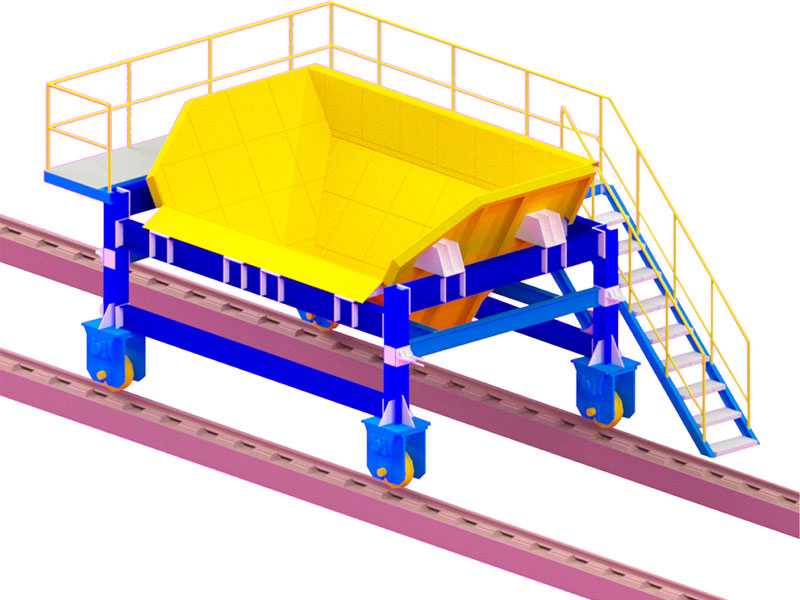

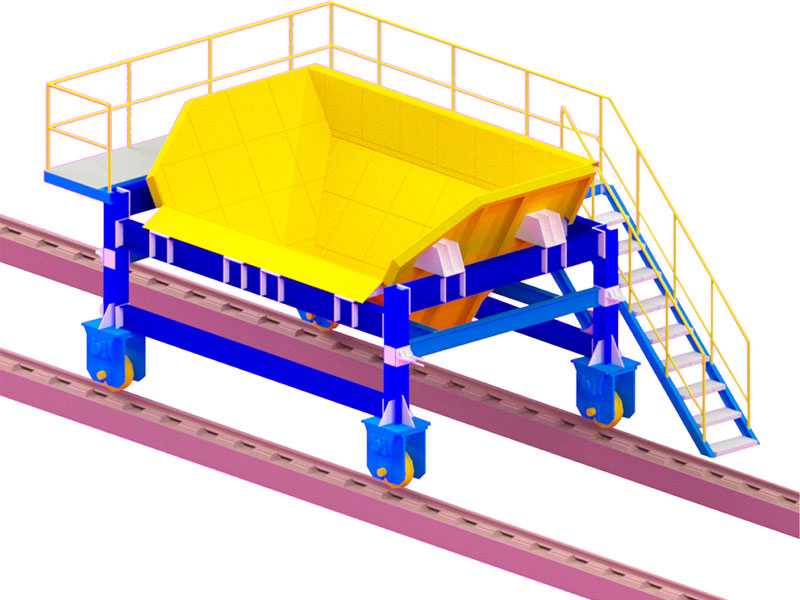

Relocatable Conveyor

Relocatable Conveyor

REXLINE ENGINEERING INDONESIA complements bulk material transport systems.

Overland Conveyors

Overland Conveyors

REXLINE overland conveyor expertise includes both surface and underground applications.

Underground Conveyors

Underground Conveyors

Strength, durability, and fire safety crucial for underground conveyor belts.

Mobile Conveyors

Mobile Conveyors

REXLINE's comprehensive range: robust, reliable bulk material handling solutions.

Transfer Stations

Transfer Stations

World-class transfer stations designed and manufactured by REXLINE ENGINEERING.

Transfer Chute

Transfer Chute

REXLINE transfer chutes optimize material flow, reduce wear and emissions

Workshop/warehouse

Workshop/warehouse

Different types of foundations and other services are provided by Rexline Engineering.