Application Of Wear Products

- Wear Pads

- Jaw crush

- Chute Linings

- Ore Chutes

- crusher Chutes

- Tripper Chutes

- Flop Gates

- Bucket Liners

- Grizzly Bars

- Lip Protectors

- Screen Plates

- Bucket Liners

- Floor Liners

- Loaders

- Knife Inserts

- crusher Bars

- Run Out Rolls

- Dump Hoppers

- crusher Hoppers

- Vibratory Feeders

- Rock Box Edges

- Surge Bin Liners

- Rock Box Liners

- Skip Liners

- Trough Liners

- Draglines

- Concentration Bins Buckets

- Transition Pieces Coal Transfer

- Shovels

- Arm & Hub Liners

- Bolt Protectors

- Truck Bed Liners

- Impact Wall Liners

- Distribution Plates

- Bucket Wheel Protection

- Conveyor Transfer Points

- Chutes Apron Feeder

- Liners Loading Pocket

- Liners Splitter/Divider

- Plates Hammer Mill

- Hopper Edges

- Wear ApronsInserts Rolling Mill Guides

CCO Wear Liners

As a genuine mining and quarrying wear liner support service, REXLINE™ have excellent quality CCO plate and weld wires. The microstructure of Cr7C3 carbide volume fraction is 50% or more which makes it one of the reliable CCO Liners on the market. The CCO range also comes in Niobium enriched composition to provide additional abrasion resistance.

- Counter Sunk

- Counter Bored

- Manufactured to complex profiles

- Fabricate and Roll Pipes

- Wear Bands

- Sieve Plates

| Standard sheet sizes (20 on 12 & 17 on 12) | ||

| Small sheets (mm) | Medium sheets (mm) | Large Sheets (mm) |

| 2670 x 1150 | 3000 x 2200 | 2870 x 2360 |

| 3000 x 1500 | 2800 x 2100 | |

| 2800 x 1150 | 2670 x 2250 | |

| 3000 x 1000 | 2800 x 1750 | |

| CCO | Hardness | (C) | (S) | (Mn) | (P) | (S) | (Cr) | (Mo) | (Ni) | (Cu) | (B) | (W) | F | Mb+Nb+ Ti+V+W | Mb+Nb+ Ti+V |

| Ultraclad 60 | >640 | 3.6–.4% | <1.87 | 1.1–2.9% | <0.032 | <0.021 | 22–34% | <0.03 | <1.1 | <0.06 | <0.02 | ||||

| Ultraclad 80 | >640 | 4.6–.4% | <1.87 | 1.1–2.9% | <0.032 | <0.021 | 22–34% | <1.1 | <0.06 | <0.02 | 2.5–13% | ||||

| Ultraclad PRO6000 | >710 | 4.5-.4% | <0.8 | 1.1-1.5% | <0.032 | <0.021 | 24–34% | 0.1-1.1% | <0.02 | 2–6% | <0.1% |

PRO 6000 Earth Moving Equipment

UltraClad PRO6000 is perfectly suitable for hard facing applications which requires impact resistance, high abrasion resistance and ability to withstand higher temperatures.

The temperature rating is up to 750°C. UltraClad range includes HTCC which is manufactured with a mix of Tungsten, Chromium Carbides and Boron Carbides in a Nickel and Silicon matrix.

The REXLINE™ Bucket loader wear plates (CCO) will outlast quenched and tempered steels by up to 12 times and white iron by up to 4 times.

The wear plates maintains the efficiency of chutes, bins, hoppers, buckets and other material handling equipment because it is quickly polished by abrading materials.

Project Overview

| MANUFACTURER | PRODUCT | PURCHASE ORDER | DATE OF PURCHASE |

|---|---|---|---|

| REXLINE™ Engineering | Chromium Carbide Overlay Wear Bands | 166581 | February, 28 2018 |

Case Study

- The client, was in dire need for a high wear resistant material for the sizing crusher. The drum inside the crusher wears out quickly hence resulting in breakdowns and high maintenance intervals. Considering these equipment’s are highly performance driven and tonnage achieved is of importance, a breakdown is last thing needed.

- REXLINE™ has developed its Chromium Carbide Steel Liner over years of reengineering and tests conducted over its chemical composition based on client requirements. REXLINE™ engineers suggested this product based on similar past applications.

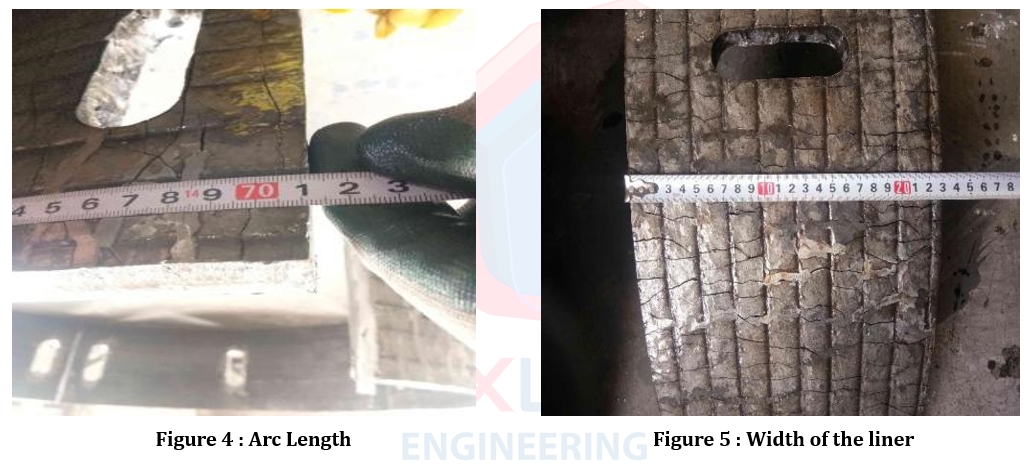

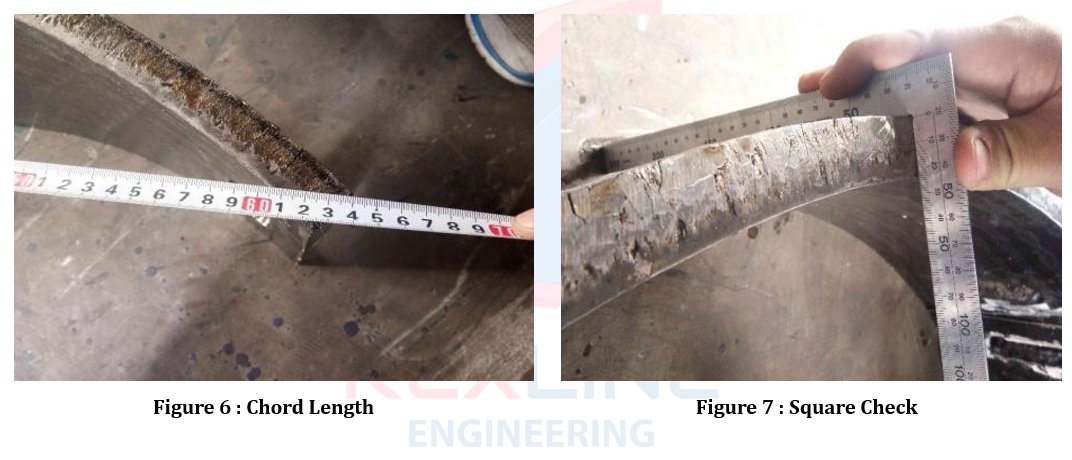

- Considering the Shape and manufacturability, these liners were welded on submerged arc welding station and were curved to suit the drum profile. As part of its services, REXLINE™ conducted QA/QC and Dimensional Checks to ensure the product is top quality and can be installed on the crusher with ease and each liner can be interchanged

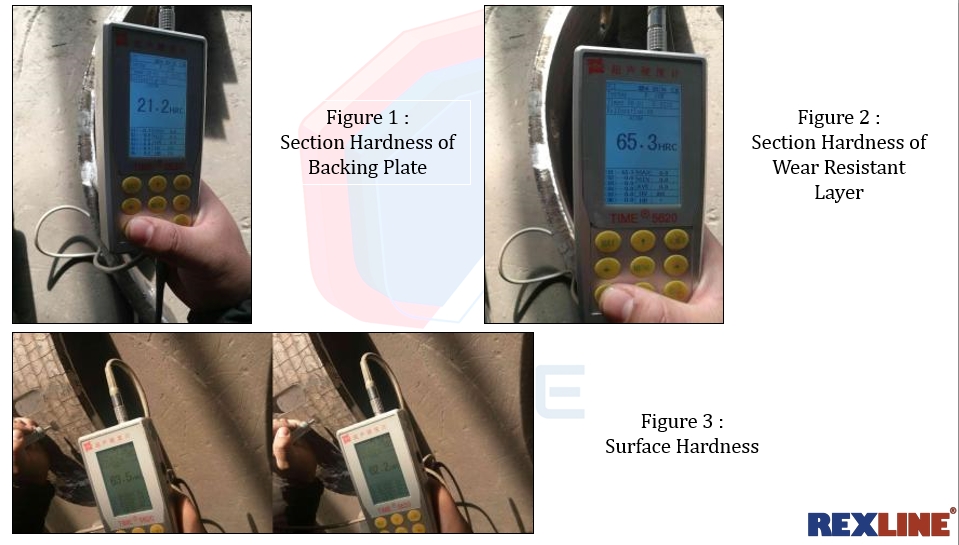

Technical Specifications

Technical Data Chemical Composition of Wear Resistant Material Deposition

| Size | 12 0n 12 | Grade | D80 | Standard | AS/NZS 2576 :2005 |

| Description | C | Cr | Mn | Si | Fe |

| Requirement | 3.00 – 5.00 | 34.0-45.0 | 0.5-2.50 | 0.50-1.50 | |

| Test Result | 4.12 | 39.4 | 1.02 | 0.81 | Bal |

| Hardness of Deposited Metal | 58 – 63 | ||||

| Recorded Hardness | 62.2 | ||||

Project Benefit Review

| Parameter | Benefits |

| Service Life | The steel liners were installed in March 2018 in the crusher. It was replaced in November 2018. Service Life : 8 Months. The service life Increased by 25% |

| Cost | Replacement and Maintenance costs of these belts was reduced by 35% Considering for a year’s worth of service life |

Visual Checks

Hardness Checks

Dimensional Checks

Ni HARD BILLETS – Liners – Buttons- Bars

REXLINE™ – Laminated Wear Blocks are unique wear resistant materials in that they combine very high wear resistant qualities of white iron (ASTM A532 15/3CrMo, 700BHN – 63HRc) with a weldable & high impact toughness mild steel through a metallurgical bond to create a product that has a exceptional resistance to impact and abrasion.

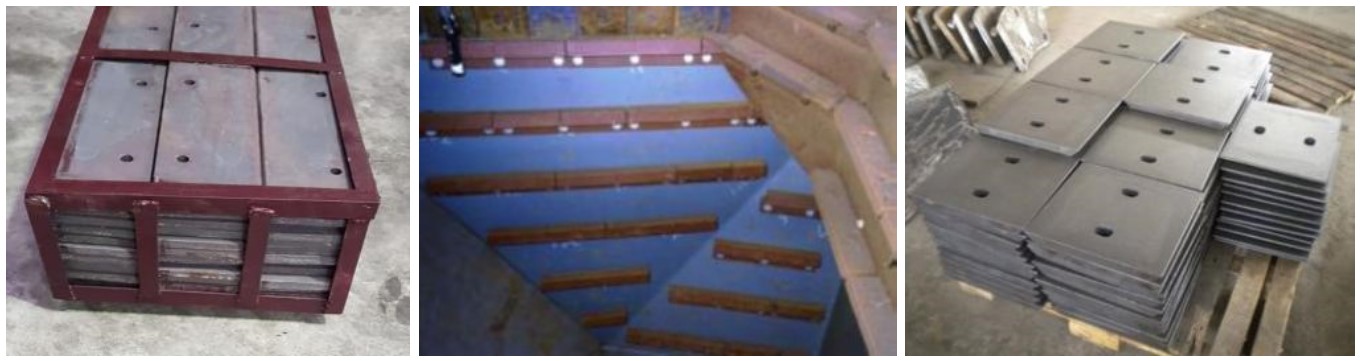

Ni-Hard material also comes in Hard skirt format with different shapes and sizes depending on the application. The additional chromium content enables the skirts to withstand extended and continuous abrasion in the application.

- Tensile Strength 630 Mpa (min)

- Shearing Strength 250 Mpa (min)

- Hardness 63 HRC

- Bimetallic Wear Plates

- Chocky Bars and Wear Buttons

- White iron wear blocks, wear bars

- Micro ledges

- Bimetallic wear pipes/Liners

- Bucket protectors

- Tungsten Carbide wear parts

- Ni-Hard wear parts

- Skid Wear Bar

| C | Si | Mn | Ni | Cr | S | P | Mo | Brinell Hardness | ||

| DuraWear | Min | 3.2 | 1.5 | 0.2 | 4 | 8 | 0.12 | 0.15 | 0.5 | 630 |

| Max | 3.6 | 2.2 | 0.8 | 5.5 | 10 | Max | Max | Max | Min | |

| DuraWearPro | Min | 2.6 | 0.6 | 1 | 4 | 26 | 0.12 | 0.15 | 1 | 650 |

| Max | 2.8 | 0.8 | Max | 5.5 | 28 | Max | Max | Max | +/-25 |

Project Overview

| MANUFACTURER | PRODUCT | PURCHASE ORDER | DATE OF PURCHASE |

|---|---|---|---|

| REXLINE™ Engineering | REXLINE™ Nihard Liners | 283362 | July, 23 2018 |

Material Information

Ni-Hard are martensitic white iron alloyed with Chromium and Nickel to provide high impact resistance and excellent abrasion resistance. Ni-Hard material also comes in Hard skirt format with different shapes and sizes depending on the application. The additional chromium content enables the skirts to withstand extended and continuous abrasion in the application.

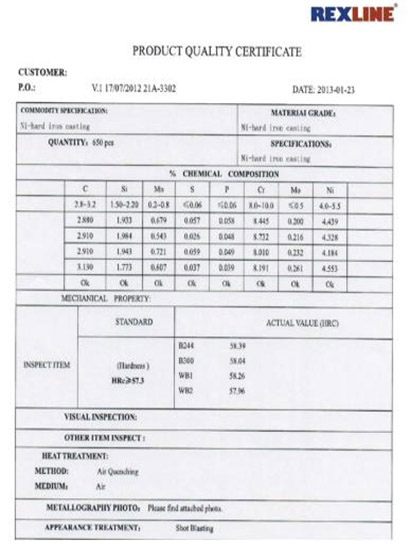

Technical Specification:

| Composition % | C | Si | Mn | Cr | Mo | Ni | P/S | Hardness |

| Ni-hard 4-600 | 2.8-3.2 | 1.5-2.2 | 0.2-0.8 | 8.0-10.0 | < 0.5 | 4.0-5.5 | < 0.06 | > HB600 |

| 42CrMo4 | 0.38-0.45 | < 0.4 | 0.6-0.9 | 0.9-1.2 | 0.15-0.3 | – | < 0.035 | Grade 8.8 |

Project Detail

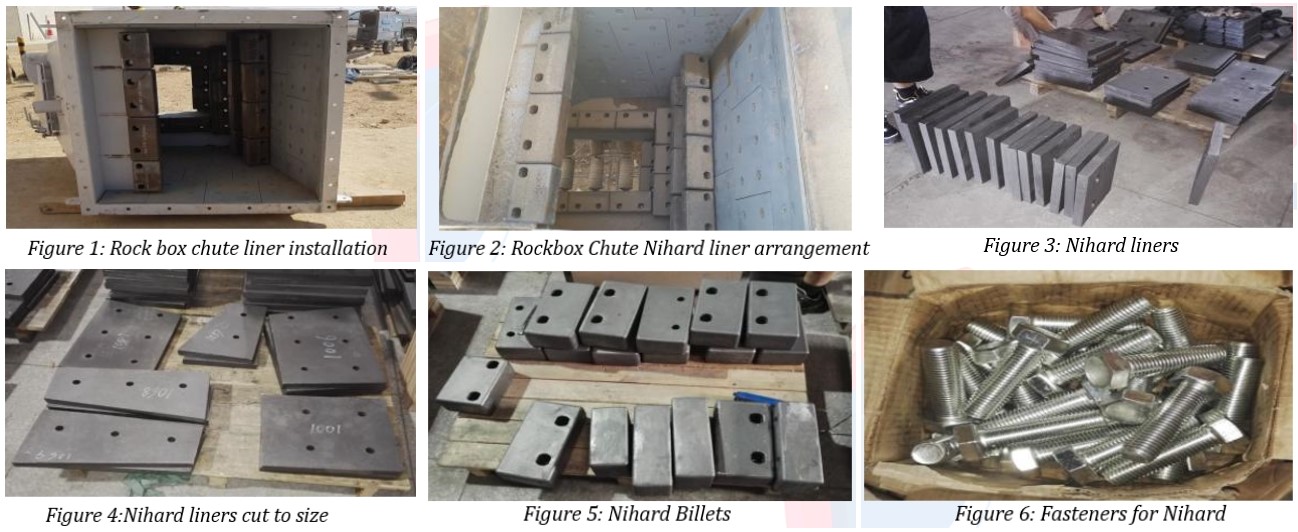

For this project, we help our client to increase the service life of one of their chutes. A chute is an equipment which is normally used conveying goods in the mining industry to transfer and channel from one conveyor system to another.

The wall of the chute wears out fast during this process because of the ores colliding and hitting against the it. We recommend them to use the REXLINE™ Ni-Hard liners for protection which can resist that high amount of abrasion and impact.

The side skirts on the equipment was 20 mm long and the client used to get flex and bows in the skirts due to the long length. After discussing with USH engineering team, the best solution to prevent this problem from happening again is by implementing reinforce steel strips in the casting to hold the shape of the skirts and prevent them from bowing and bending.

| Composition % | C | Si | Mn | Cr | Mo | Ni | P/S | Hardness |

| Ni-hard 4-600 | 2.8-3.2 | 1.5-2.2 | 0.2-0.8 | 8.0-10.0 | < 0.5 | 4.0-5.5 | < 0.06 | > HB600 |

| 42CrMo4 | 0.38-0.45 | < 0.4 | 0.6-0.9 | 0.9-1.2 | 0.15-0.3 | – | < 0.035 | Grade 8.8 |

Conclusion & Service Life

Using REXLINE™ Ni-hard liners, the service life of this equipment increased by 25%.

| Composition % | C | Si | Mn | Cr | Mo | Ni | P/S | Hardness |

| Ni-hard 4-600 | 2.8-3.2 | 1.5-2.2 | 0.2-0.8 | 8.0-10.0 | < 0.5 | 4.0-5.5 | < 0.06 | > HB600 |

| 42CrMo4 | 0.38-0.45 | < 0.4 | 0.6-0.9 | 0.9-1.2 | 0.15-0.3 | – | < 0.035 | Grade 8.8 |

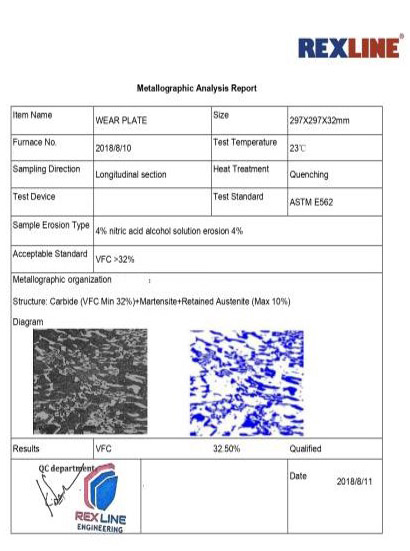

Product Quality Certificate

Nihard Wear Liners

Ni-Hard Wear Products

For over half a century, Ni-hard has been the number one choice for industrial processed demanding extreme abrasion resistance. Because of Its well proven, low-cost characteristics it is used in the mining, power, cement, ceramic, paint, dredging, coal-coke, steel and foundry industries. wear backs and metalworking rolls-the range of properties inherent in the different grades of Ni-hard has made it a worldwide success.

| Table 1 Compositions of Ni-hard 4 irons | ||||||||

| Grade | C | Si | Mn | S | P | Ni | Cr | Mo* |

| Ni-hard 4 | 2.6-3.2 | 1.8-2.0 | 0.4-0.6 | max 0.1 | max 0.06 | 4.5-6.5 | 8.0-9.0 | 0-0.4 |

| Table 2 Typical mechanical and physical properties of Ni-hard 4 | |

| Brinell | 550-650 |

| Vickers | 650-820 |

| Rockwell C | 56-60 |

| Tensile Strength[MPa] | 500-650 |

| Transverse strength[Mpa] | 600-800 |

| Deflection [mm] | 2.0-2.8 |

| Compressive strength[Mpa] | 280-310 |

| Specific density[g/cm] | 7.75 |

Project Overview

| MANUFACTURER | PRODUCT | EQUIPMENT | DATE OF PURCHASE |

|---|---|---|---|

| REXLINE™ Engineering | Nihard Wear Liners & Billets | Chute | April, 2018 |

Project Overview

| MANUFACTURER | PRODUCT | EQUIPMENT | DATE OF PURCHASE |

|---|---|---|---|

| REXLINE™ Engineering | Chrome Iron Nihard Liners | Inlet Feeder Chute | April, 2018 |