Belt Weigher

PT Rexline Engineering Indonesia manufactures microprocessor based electronic belt weighers incorporating the latest state-of-the-art technology for continuous weighing applications in cement, steel, chemical, petrochemical industries and coal handling plants.

Belt Weighers consist of three major elements:

- The weigh bridge assembly with precise strain gauge load cell/bending beam load.

- The belt speed sensor assembly, and the electronic cabinet often referred as the totaliser or the integrator.

Each serves a distinct function in the process of accurately weighing material moving on the belt. Different models of scale carriage are available depending upon the application, scale capacity and belt speed.

- Capacities from a fraction of tonne to 10,000

- Simple rugged and unitized scale assembly for easy

- Super precision stainless steel strain gauge load cell applied in tension for highly accurate load

- Special trunion bushes to absorb normal shocks and transverse

- Weigh idler deflection less than 025 mm at full load.

- Brushless digital tacho provides accurate measurement of

- Fully digital with microprocessor and battery back-up

- Fully automatic tare and span

- Self-checking diagnostics for fault

- Special electronic calibration facility for frequent calibration checks without handling standard

Salient features :

- Proven conveyor scale software for microprocessor based integrator.

- Micromate is a true digital device with digital readout, digital processing, bi-directional integration and totalisation and drift free operation.

- No internal adjustments by potentiometers.

- Automatic calibration of zero span and selectable auto zero tracking available (in zero track mode, tare is updated automatically whenever the belt runs empty.)

- Simple one time entry of data and instructions via pushbuttons and keyboard.

- Bright easy to read display of rate and total.

- Excellent temperature stability.

- Backed up by excellent PEL know-how and service availability.

- Standard execution : ± 0.5 % of actual rate.

- Special execution : ± 0.1 & 0.25 % of actual rate.

Accuracy:

- Standard execution : ± 0.5 % of actual rate.

- Special execution : ± 0.1 & 0.25 % of actual rate.

Weighfeeder

PT Rexline Engineering Indonesia microprocessor based digital weigh feeders as per design of HASLER International-France, incorporating their state-of-the-art technology for continuous control and proportioning application in cement, steel, fertilizer, chemicals, petrochemical and other industries.

Principle of operation:

PT Rexline Engineering Indonesia Gravimetric weigh feeder is a variable speed small conveyor incorporating belt weighing and speed control system. The flow rate is held constant by varying the speed inversely with respect to belt load.

Set point controller ( a built in feature in all Hasler controller ) allows setting of required rate and provides a signal to raise or lower the speed of the belt.

For additional controls and communication facility, required signals are available from the weigh feeder control panel to connect it to a PLC or a supervisory computer either direct or using MODBUS/PROFIBUS etc. making it a part of distributed digital control system. Measurement of flow rate and control are all through 32 bit microprocessor based digital techniques ensuring high reliability and accuracy to the level of 0.25% which is not known in the industry presently.

For materials having sluggish flow characteristic mass flow bins, vibrators, screw feeders, rotary air lock feeders are provided to allow the material to lend themselves to control.

Salient features :

- Fully automatic zero and span calibration.

- Highly reliable 32 bit microprocessor based controller. with precise temperature compensated load cell for drift-free operation and control.

- Highly precise vibrating wire load cell with resolution of 1:1,000,000 . No calibration ever required for the load cell as also temperature compensated for life

- No field calibration of load cell required in case of digital load cell. In case of analog load cell simple calibration with static loads or by electronic calibration.

- Can be operated from any location viz: local panel, main panel or control room.

- Precision machined rollers used in weigh zone for achieving high accuracy.

- Rubber lagged crowned pulley is used to avoid belt slip.

- Digital speed sensor mounted on non drive pulley shaft to sense the actual belt speed.

- Choice of shaft mounted heli worm, or worm gear reduction provides trouble-free power at required speed if space is not a constraint.

- Suitable pre-feeders can be provided depending upon flow characteristics.

- Rigid heavy duty construction.

Accuracy:

- 25% to 0.5% through out the control range of 1:10 and 1:20.

Automatic Weighing & Bagging Machine

PT Rexline Engineering Indonesia manufactures electromechanical as well as electronic microprocessor based weighing and bagging machines for high speed automatic weighing and bagging of variety of materials such as fertilizers, food grains, sugar, cattle feed, PVC granules, cereals, coal, coke, chemical powder, flour, flakes, soda ash, etc.

Machines are designed and manufactured adopting the latest technological developments in the field of accurate weighing. The weighing and bagging machines are available in different models like gravity/belt/screw feeder or vibrating feeder tray. These machines are available as a net or gross model, in mild steel or stainless steel construction.

Electronic type microprocessor based automatic weighing & bagging machines incorporating highly accurate strain gauge load cells and latest state-of-the-art fully digital microprocessor controller are available for capacity upto 900 bags/hour with an accuracy of ± 50 gms or better over a range of 25 kgs to 100 kgs as well as jumbo bags of 1 tonne.

Salient features :

- Powerful 16 bit processor is used for electronic bagging

- Different models available depending upon the flow characteristic of the

- Fully digital calibration and parameter set up per interactive dialogues for different weighing

- RS485 serial channel for printer, data output, serial

- Parallel I/O interface with inputs and outputs, which can drive the magnetic valves

- Operation and display terminal suitable for panel mounting or table

- Material flows after flow compensation for coarse and fine cut Thus the filling accuracy is independent of material density.

- Auto check stop feature available to check and remove the bags which are out of

Accuracy:

- Accuracy ranges from ± 20 grams to 100 grams depending upon material flow characteristics and bagging

Wagon & Truck Loader

To solve the ever increasing problem with handling of bags in process plants, PT Rexline Engineering Indonesia has join hands with M/s. BOUBIELA of France to manufacture Wagon and Truck Loaders. Boubiela have got to their credit, thousands of satisfied customers all over the world manufacturing/dealing in Fertilizer/Sugar/Chemicals/Cattle Feed Plants/Food Corporations etc.

Different models of truck loaders up to a maximum capacity of handling 3000 bags per hour each of 50 Kgs. can be supplied for loading, stacking and lining up bags onto trucks. Wagon Loaders in different models upto 3000 bags per hour are also available. The loading jib is telescopic with 180° rotation and can be lifted by a mechanical or hydraulic jack.

Simultaneous loading of number of trucks as well as wagons on parallel track can be achieved with REI-BOUBIELA make Wagon and Truck Loaders.

Overband Self Cleaning Type Electro Magnetic Separators

A must for separation of tramp iron pieces and for avoiding interruption and damage to major equipment in the process plants like Coal handling Plants of Thermal Power Stations, Cement and Sugar Industry, Foundries, Fertilizers & Chemicals Industries, Food and Plastic Industries etc.

PT Rexline Engineering Indonesia magnets are available in copper/aluminium coil winding with F/H Class insulation and suitable for belt width ranging from 400 mm to 2000 mm, operating heights upto 700 mm with lifting capacity of steel ball of diameter 25 mm and above with maximum weight of 50 Kgs depending upon shape and size of tramp iron pieces.

Metal Detectors

PT Rexline Engineering Indonesia manufactures metal detectors as per Boekels’ design with latest technology incorporation integrating circuits, styroflex capacitors, metal film resistors, temperature compensated pot core transformers, active filters etc. These are widely used in:

- Mining and material handling/processing industries to prevent damage to crushers, mills, elevators, feeding

- Chemical Industry to prevent damage to grinding mills and processing glass lined vessels and to avoid metallic

- Wood and timber industries to prevent damage to saws, chippers, particle board presses

- Plastic and moulding Industries to prevent damage to press and

- Food, Tobacco, Tea & Pharmaceutical industries to protect kneading machines and presses and also to inspect final product for metallic contamination.

- Clay and brick industries to protect

PT Rexline Engineering Indonesia Metal Detector consists of search coil unit and electronic control unit. These are available in various Models depending upon width of conveyor belt and burden height. Sand bag marker for spot locating the detected metal contamination and auto testing device for periodic checking of sensitivity are provided as optional accessories.

Shiftable Conveyors

PT Rexline Engineering Indonesia undertakes design and manufacture of conveyors from 600 mm to 2000 mm belt width. The conveyors can be supplied as horizontal conveyors, inclined conveyors, reversible and non-reversible shuttle conveyors, tripper cars and tripper conveyors. Special mobile conveyors can be designed for material stacking and de-staking application as also for barge loading.

Electric Hoist

PT Rexline Engineering Indonesia electric hoists are designed in accordance with international standards and also as per “Rules for design of serial lifting equipment” issued by Federation of European Hoist Manufactures (FEM). Present manufacturing range includes hoist up to 16 tons lifting capacity.

PT Rexline Engineering Indonesia hoists incorporate fan cooled crane duty brake motor with class ‘F’ insulation, specially designed rope guide manufactured from polyethylene and hoist barrel with machine-cut grooves made from seamless tubes with high tensile strength. Gearbox or motor can be removed independently. PBL Hoists suitable for monorail and trolley drive – either for straight beam or curved beam – and double girder.

Belt Feeder

Features :

- Heavy duty Designed for rugged use

- Can be Fixed or movable

- Power transmission through electric motor and planetary gearbox, shaft mounted on the pulley with torque on the structure

- Primary cleaner and plow

- Drive Shaft and return pulley guards

Benefits:

- Ease of maintenance due to rugged design and features

- Easy to install

- Flexible due to fixed or mobile

- Long, Extended life

- Designed for maximum efficiency Economical

Bucket Elevators

One of the most efficient way to elevate bulk materials vertically is with a bucket elevators.

A Bucket Elevator consists of a series of buckets attached to a belt or chain with pulleys or sprockets located at the top and bottom of the unit. The buckets are located in a casing or housing to contain the material. Bulk materials are loaded into each bucket as the bucket moves past an inlet point. PEL manufactures and designs wide variety of bucket elevators based on characteristics of the bulk material and process requirements.

Advantages of using Bucket Elevators:

- Designed to handle a wide variety of bulk materials-from average to very free flowing

- Completely Enclosed for Dust and weather Tight

- Easy to Install and Operate

- Low maintenance

- Inlet Section Can be Control Fed Or Flood Loaded with Bulk

- High reliability

Duplex Weighing and Bagging Machine

Our Microprocessor based load cell type Electronic Weighing and Bagging Machine Model NEM 50/II Twin Known for Faster Bagging rate and Accuracy. It Consists of Two Separate Hopper and two separate Weighing Receptacle with Single Sack grip.

The Whole weighing receptacle assembly is hanged in such a way that the total load of receptacle is passed on to the four Loadcells. In turn the load cell generates an electrical systems equal to weight. This signal is fed to Microprocessor Controller that process this signals and accordingly control all function of weighing process .Due to Introduction of Loadcells, the System accuracy is improved and with the help of microprocessor the whole System becomes a closed loop System making it more precise compare to open loop system.

The Above System has additional Facilities of having display of each and every weight, error signals display on fault occurrence, a self diagnostic feature and an optional online printing facility in case if it is required.

Accuracy:

Accuracy ranges from ± 20 grams to 100 grams depending upon material flow characteristics and bagging speed.

GEARBOXES

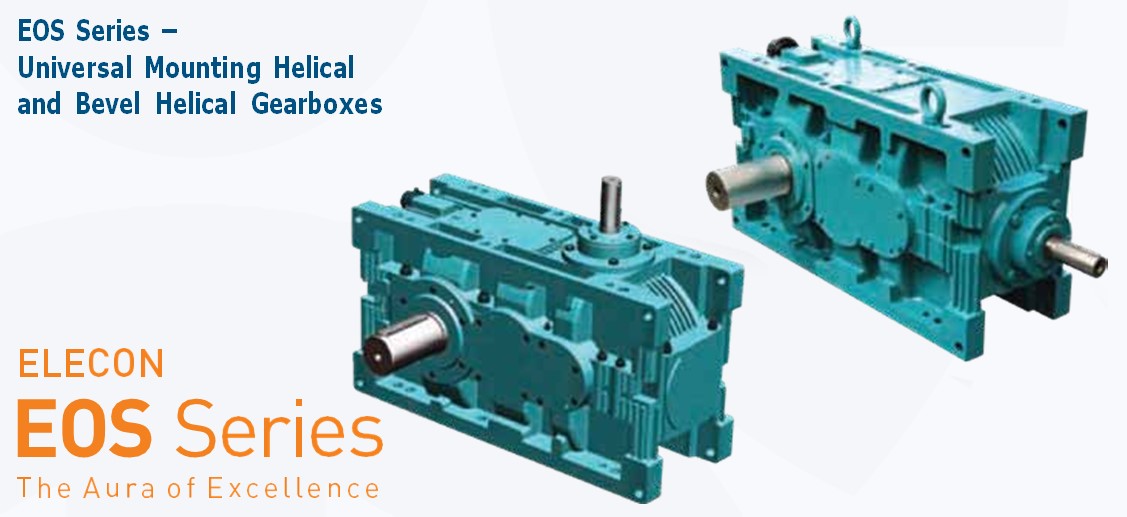

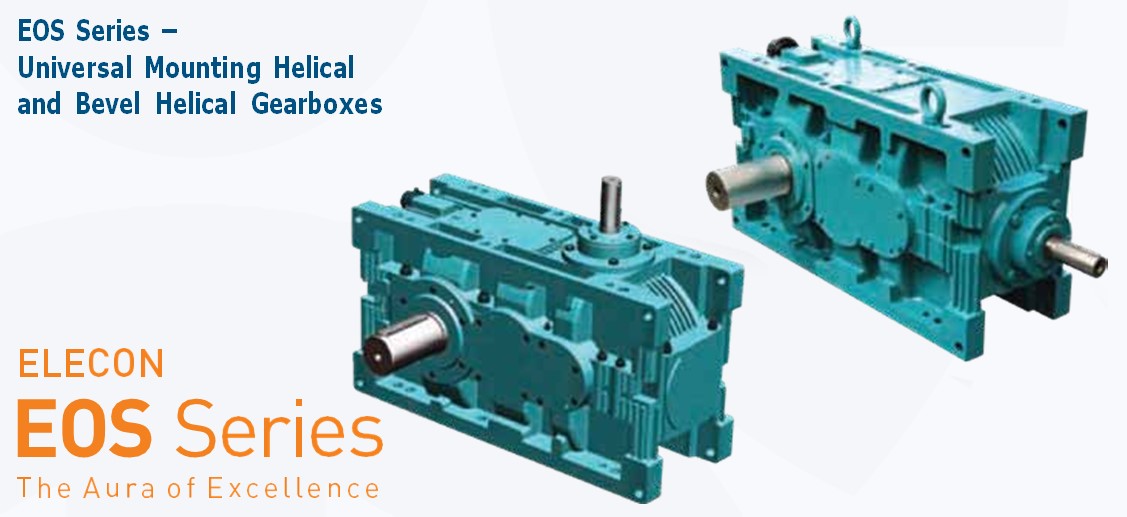

For more than 60 years Elecon has been gearing economies worldwide by supplying industries with our wide range of Power Transmission equipment. We have continuously strived to be a step ahead in technology by innovating and providing you with the most optimal solutions from our state-of-the-art facilities, keeping in mind the ever-changing requirements of the industry.

Elecon is now proud to present to you our next generation of industrial gearboxes featuring a variety of improvements such as higher torque ratings, better thermal capacities, universal mounting and wider range of accessories to enable adaptation to the most stringent requirements. Gearboxes are of split design to enable easy maintenance and are rated according to the latest DIN and AGMA standards.

Technical Specifications

| Options | Helical (parallel shaft), Bevel Helical (right angle shaft), Compact – Bevel Helical (right angle) |

| Mounting Options | Horizontal, Vertical, Over-driven, Under-driven, Torque Arm |

| Input Power | Upto 4,825 KW |

| Output Torque | Upto 132,000 Nm |

| Gear Ratios | 1.25/1 to 560/1 |

| Output Shaft | Upto 190 mm diameter (Solid Shaft), Upto 220 mm diameter (Hollow Shaft) |

| Optional Features | Motor Adaptor, Integral Backstop, Shrink Disc, Torque Arm, Forced Lubrication System, Cooling Coil, Integral Fan, Integral Output Flange, Double Extended Shafts |

EOS Series – Universal Mounting Helical and Bevel Helical Gearboxes

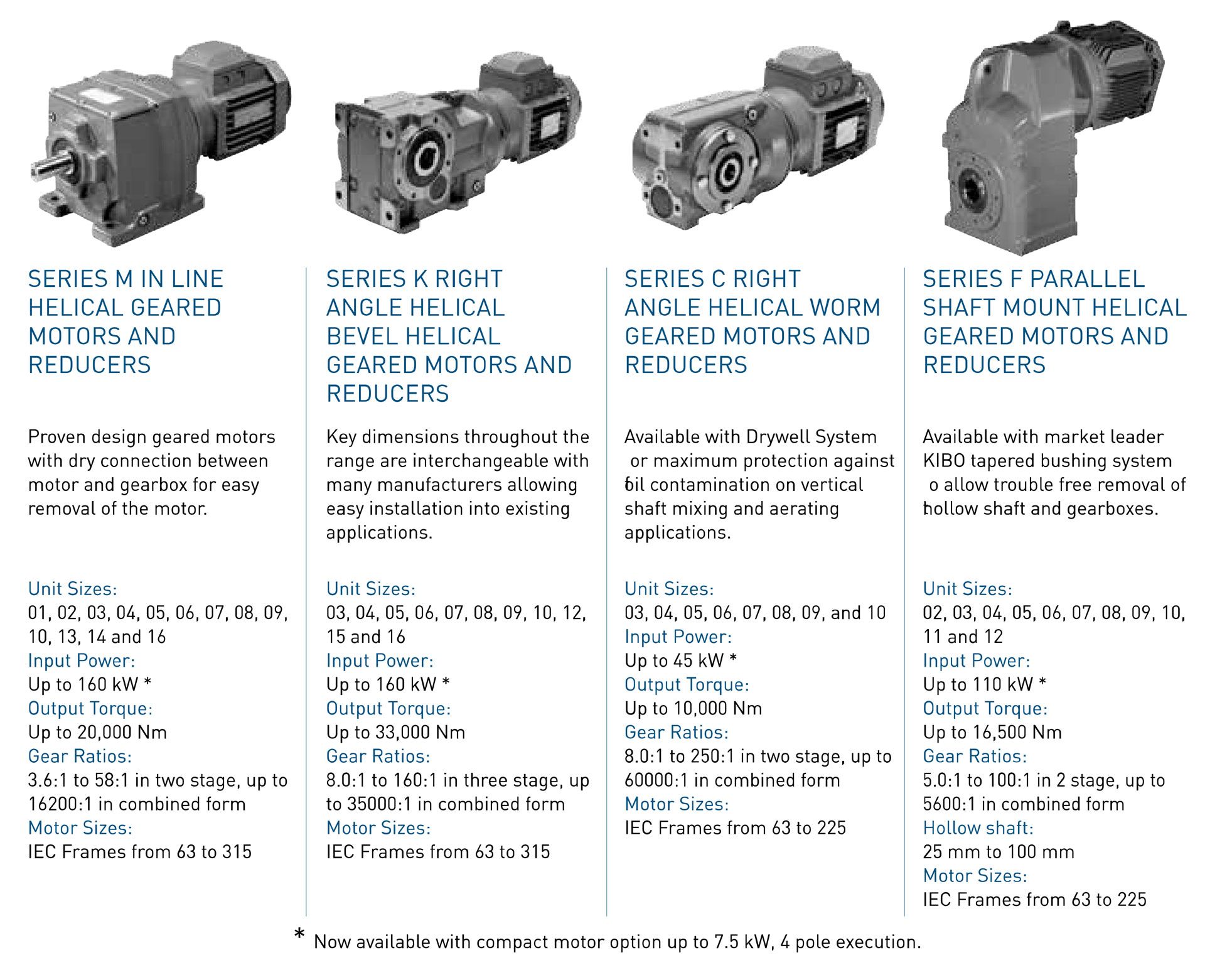

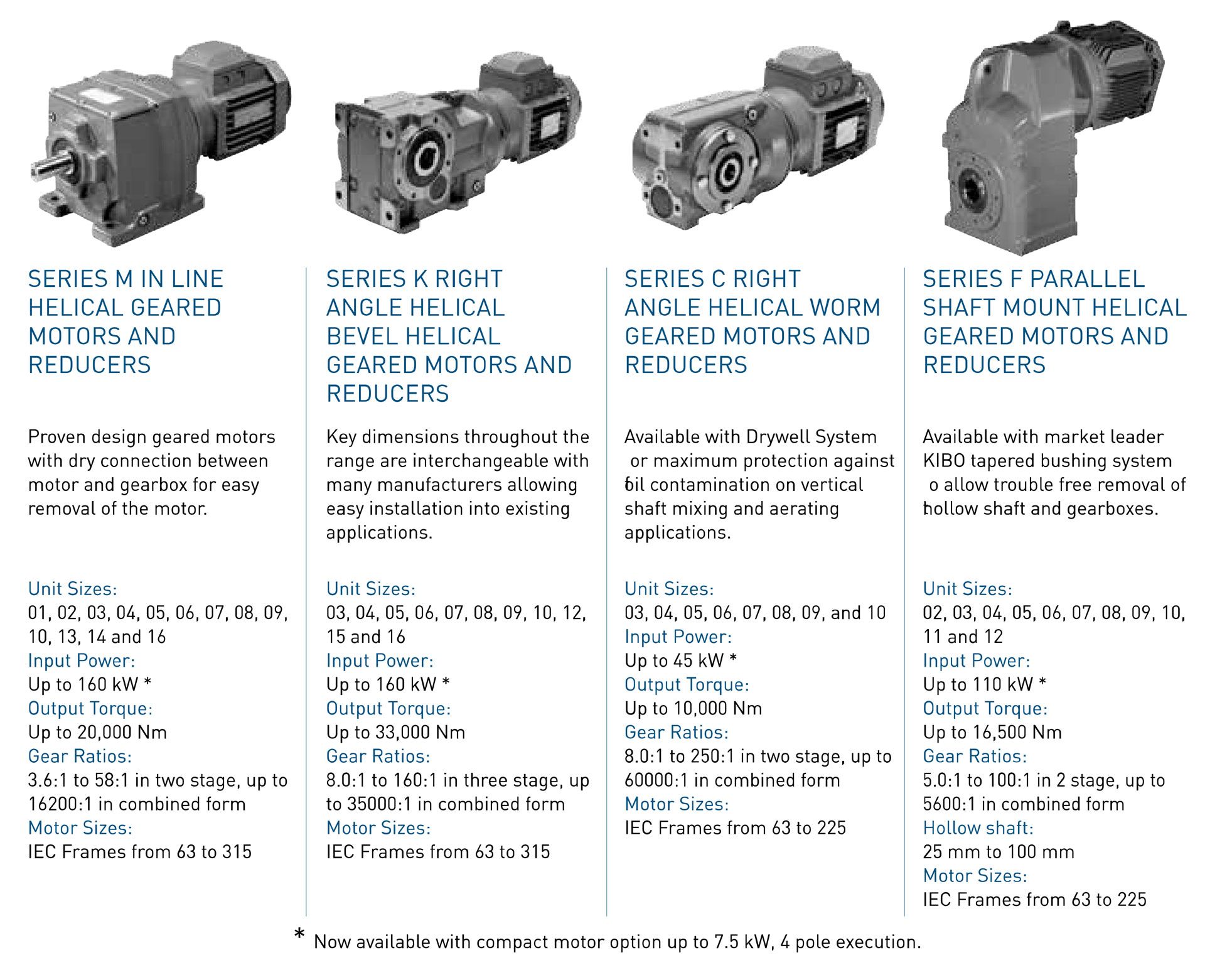

GEARED MOTOR

THROUGH LIFE COSTS

Whether you use drive and linear motion systems in your plant production line, or are a machine builder wishing to offer your customer the most reliable machine possible, we recognise the importance of minimising through-life cost.

A combination of rugged reliability, providing maximum life span and user friendly design, enabling easy maintenance, ensures that the products we offer are easy to live with, giving you peace of mind and allowing you to focus on the important areas of your day to day business.