AREAS OF EXPERTISE

Rexline Engineering Indonesia is capable of handling various scales of lining and coating work for all project sizes. We ensure that each step of the process is carried out to your specification. Our team takes great pride in quality workmanship, expertise and product knowledge that deliver the essential corrosion prevention needed for long-term asset protection.

Our Capabilities

- Rubber Lining

- Ceramic Lining

- CCO / Ni Hard Lining FRP Lining

- Wear Resistant Coating Epoxy Coating Sandblasting

- Standard and custom lining and coating applications available

- On-Site & In-Workshop application and repairs Internal & External parts of plant equipment, e.g. tanks, pipes, agitators, chutes, diffusers, and many more

- Consultation service for surface preparation, corrosion & wear protection and specialty industrial linings & coatings

Rubber Lining

Dependable & Long Term Protection for Plant Equipment against Corrosion and Abrasion: Rexline Hard Rubber, Rexline Soft Rubber, Rexline Chloroprene Rubber, Rexline Butyl Rubber.

Application

- Storage Tanks

- Vessels

- Circulation Water Piping

- Condensers

- Water Box & Pipes

- Heat Exchanger Systems

- Pumps

- Cyclones

- Bins & Hoppers

- Scrubbers

- Conveyor Discharge Chutes

- Transportation Lorries

Storage Tank (Acid or Base Tank) and Condensor & CWP Pipe images are given below:

Typical Properties of

| Rexline Hard Rubber | Rexline Soft Rubber | Rexline Chloroprene Rubber | Rexline Butyl Rubber |

Chemical Resistant | Excellent | Good | Good | Excellent |

Heat Resistant | Good | Fair | Good | Excellent |

Weather Resistance | Good | Good | Excellent | Good |

Abrasion Resistance | Not Recommended | Excellent | Good | Fair |

Vapor Permeability | Excellent | Fair | Good | Excellent |

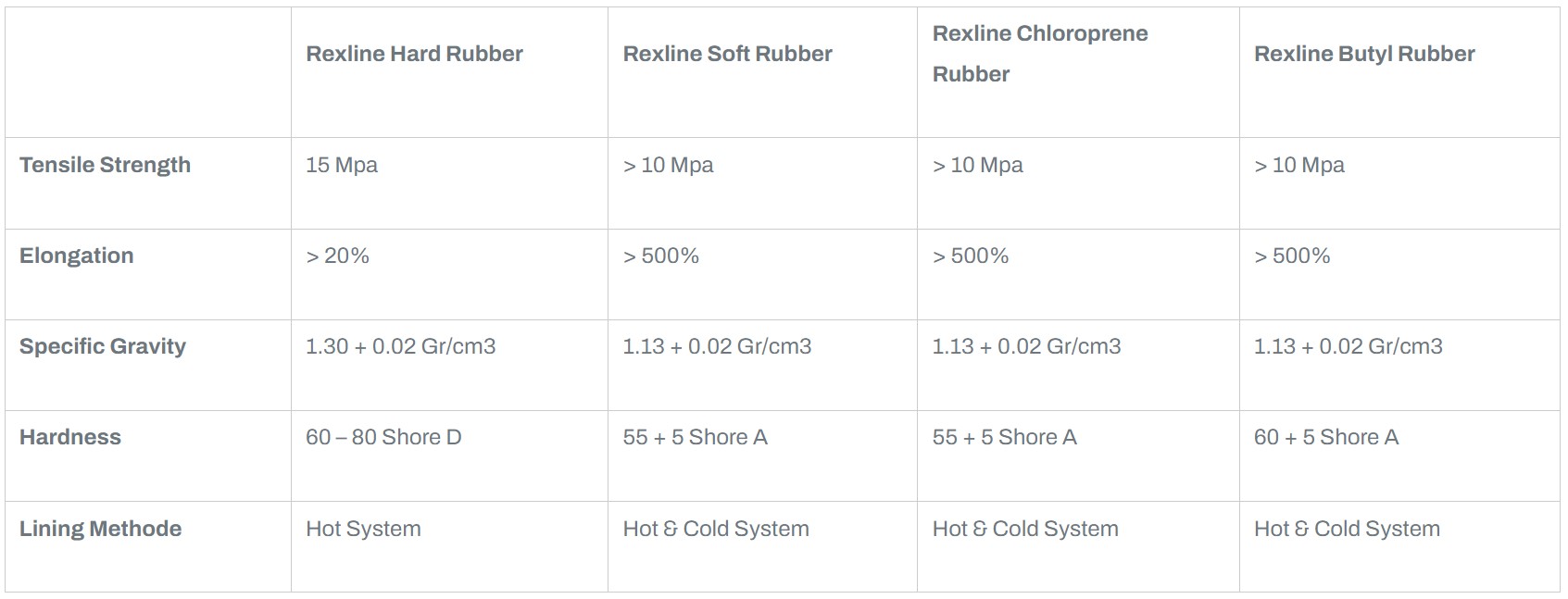

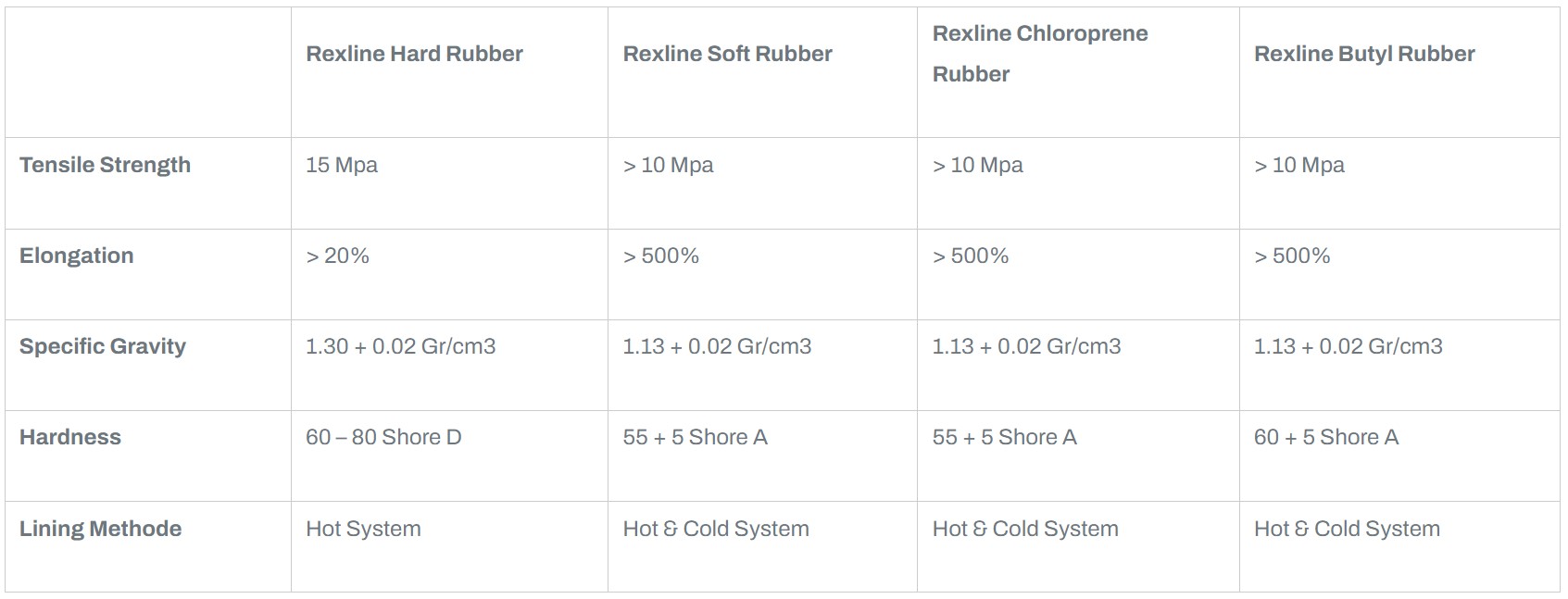

Typical Properties of

Physical Properties

| Rexline Hard Rubber | Rexline Soft Rubber | Rexline Chloroprene Rubber | Rexline Butyl Rubber |

Tensile Strength | 15 Mpa | > 10 Mpa | > 10 Mpa | > 10 Mpa |

Elongation | > 20% | > 500% | > 500% | > 500% |

Specific Gravity | 1.30 + 0.02 Gr/cm3 | 1.13 + 0.02 Gr/cm3 | 1.13 + 0.02 Gr/cm3 | 1.13 + 0.02 Gr/cm3 |

Hardness | 60 – 80 Shore D | 55 + 5 Shore A | 55 + 5 Shore A | 60 + 5 Shore A |

Lining Methode | Hot System | Hot & Cold System | Hot & Cold System | Hot & Cold System |

Physical Properties

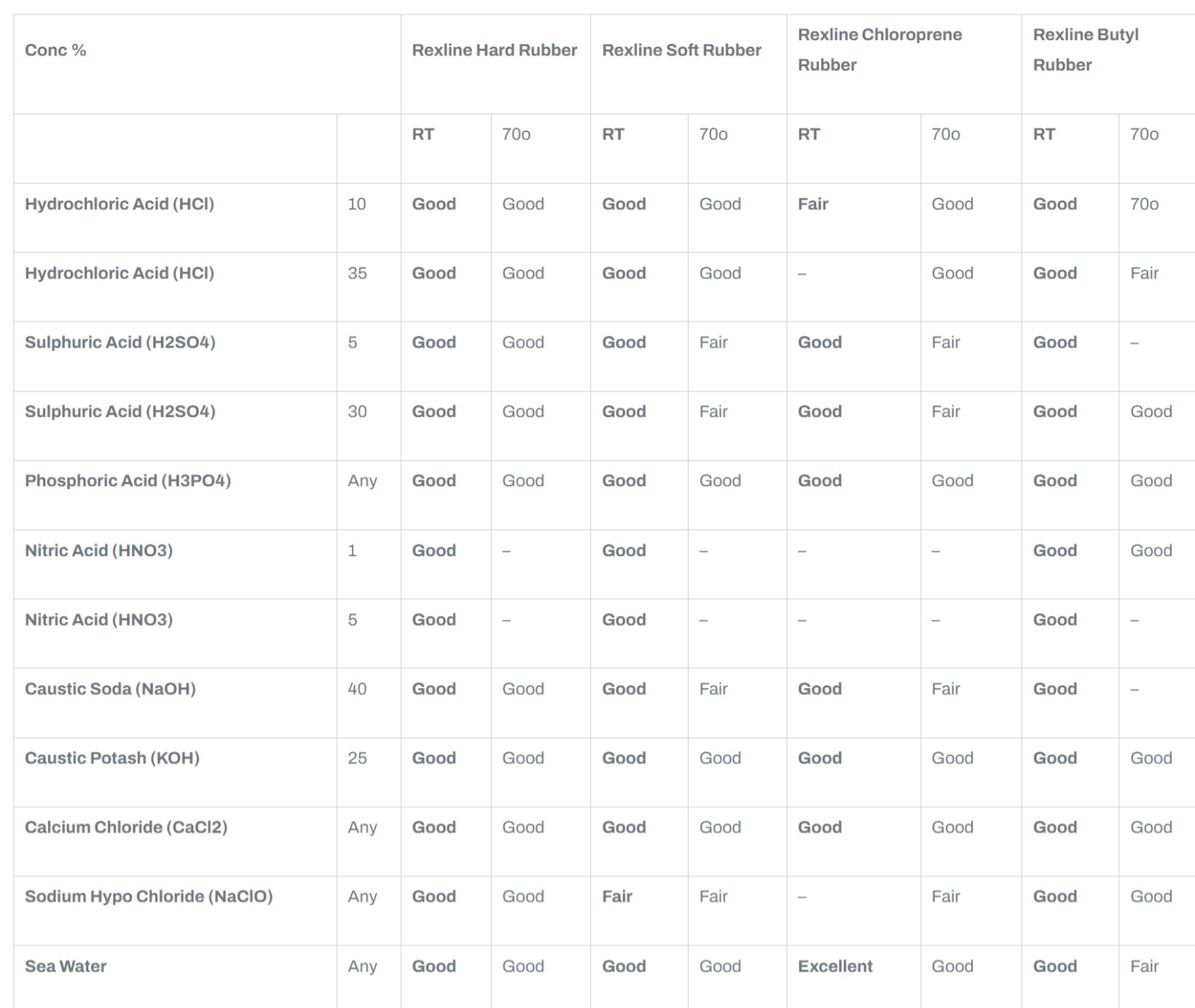

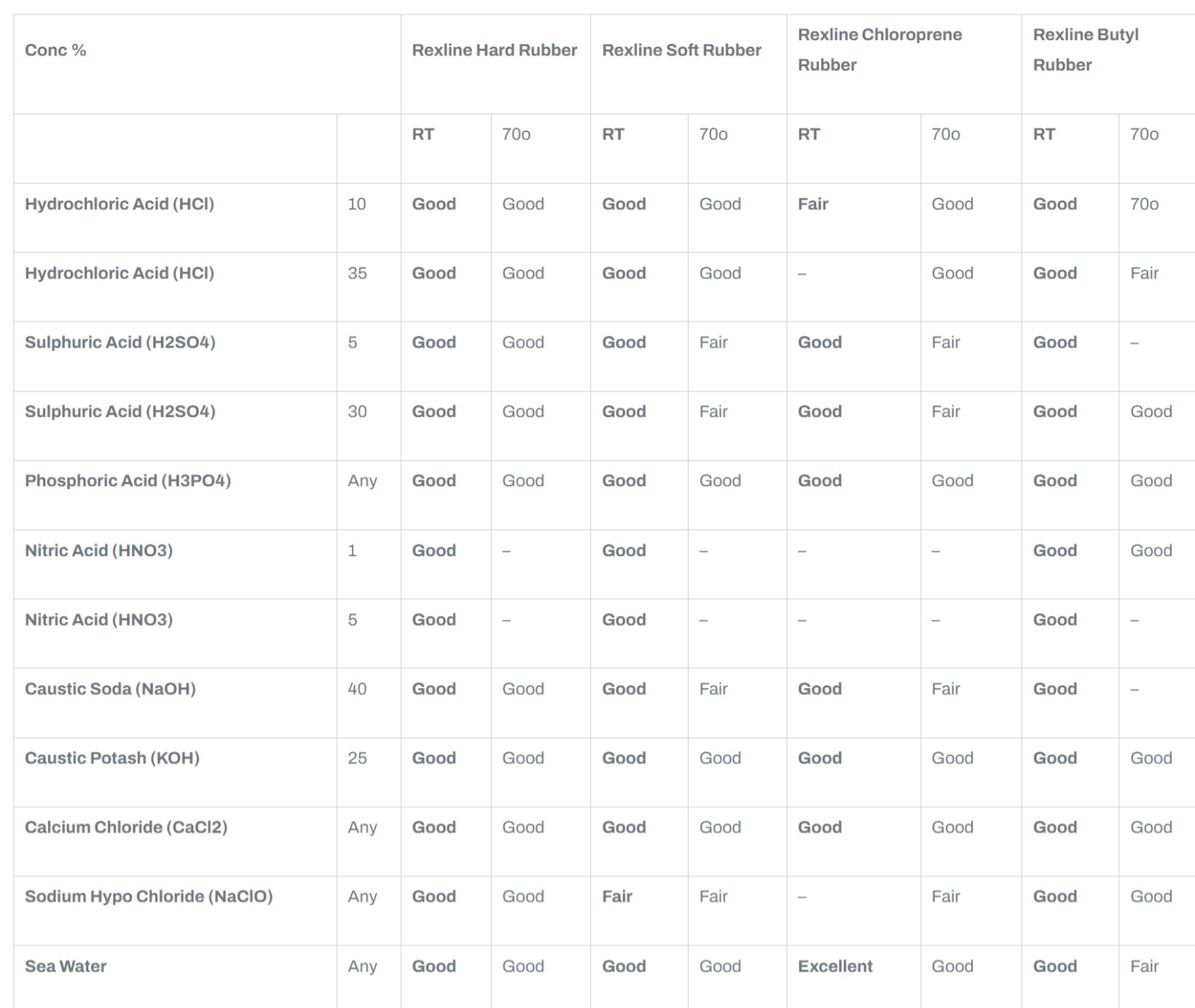

Chemical Resistant Charts

| Conc % | Rexline Hard Rubber | Rexline Soft Rubber | Rexline Chloroprene Rubber | Rexline Butyl Rubber | |||||

| RT | 70o | RT | 70o | RT | 70o | RT | 70o | ||

| Hydrochloric Acid (HCl) | 10 | Good | Good | Good | Good | Fair | Good | Good | 70o |

| Hydrochloric Acid (HCl) | 35 | Good | Good | Good | Good | – | Good | Good | Fair |

| Sulphuric Acid (H2SO4) | 5 | Good | Good | Good | Fair | Good | Fair | Good | – |

| Sulphuric Acid (H2SO4) | 30 | Good | Good | Good | Fair | Good | Fair | Good | Good |

| Phosphoric Acid (H3PO4) | Any | Good | Good | Good | Good | Good | Good | Good | Good |

| Nitric Acid (HNO3) | 1 | Good | – | Good | – | – | – | Good | Good |

| Nitric Acid (HNO3) | 5 | Good | – | Good | – | – | – | Good | – |

| Caustic Soda (NaOH) | 40 | Good | Good | Good | Fair | Good | Fair | Good | – |

| Caustic Potash (KOH) | 25 | Good | Good | Good | Good | Good | Good | Good | Good |

| Calcium Chloride (CaCl2) | Any | Good | Good | Good | Good | Good | Good | Good | Good |

| Sodium Hypo Chloride (NaClO) | Any | Good | Good | Fair | Fair | – | Fair | Good | Good |

| Sea Water | Any | Good | Good | Good | Good | Excellent | Good | Good | Fair |

Chemical Resistant Charts

Inspection

Our highly trained technicians conduct strict inspections and produce detailed report to maintain consistent quality.

Surface Preparation Inspection

Environmental Condition Test

Standard: BS 6374 Part 5 Recommended:

- Steel Temperature: 10-40°C

- Relative Humidity : max 80%

- Dew Point : > 4°C

Final Inspection for Lining & Coating

Thickness Test

Standard: BS 6374 Part 5 The thickness is measured to ensure it is within the tolerance.

Hardness Test

Standard: ASTM D 2240 The thickness is measured to ensure it is within the tolerance.

Hardness Test

Standard: BS 6374 Part 5 The entire lining area is checked to ensure there are no leaks.REXBOND ADHESIVE

Rexline Engineering is one of the largest Adhesives and Chemical manufacturer globally. We are able to offer clients a full range of Chemicals from primers to adhesives.

Our RexBond Rubber Cement has been specially formulated and engineered to offer secure bonding to any substrate. RexBond Rubber Cement is becoming a fast growing industry name due its long tack time which makes for easy application for rubber lining applicators.

REXBOND Rubber Cement

- REXBOND Rubber Cement is a 2 Part Component Adhesive with REX-HARDENER re- curing agent.

- REXBOND RC offers a high initial grab, heat resistance and good open time.

- REXBOND RC has been specially formulated and engineered to bond rubber to rubber and rubber to metal in mining applications.

RX2000 Adhesive for Belt Splicing RX4000 Adhesive for Rubber Lining

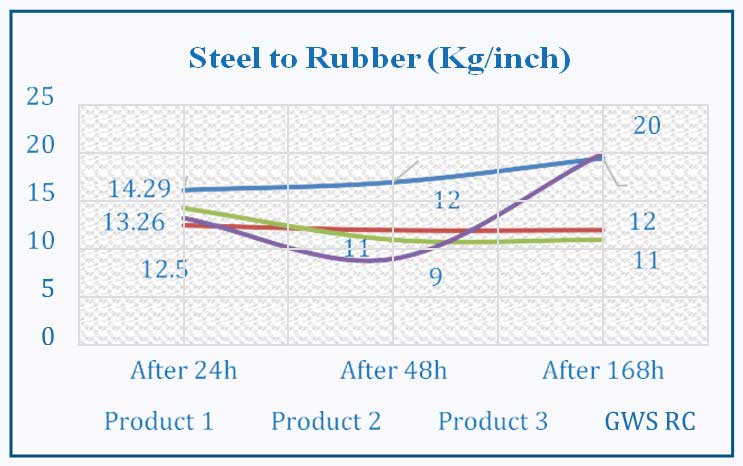

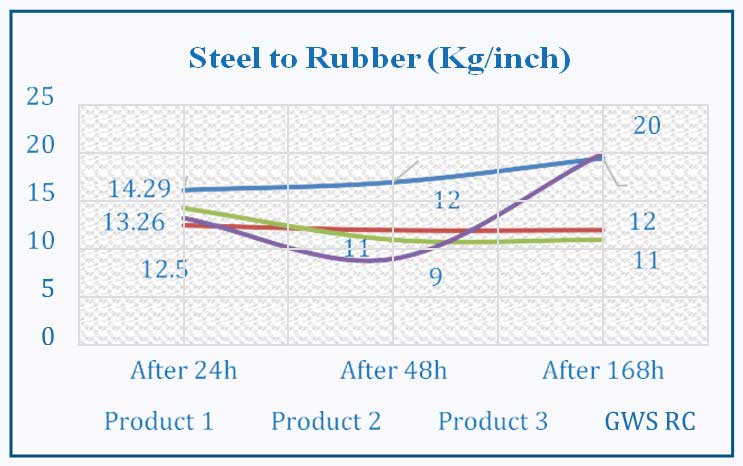

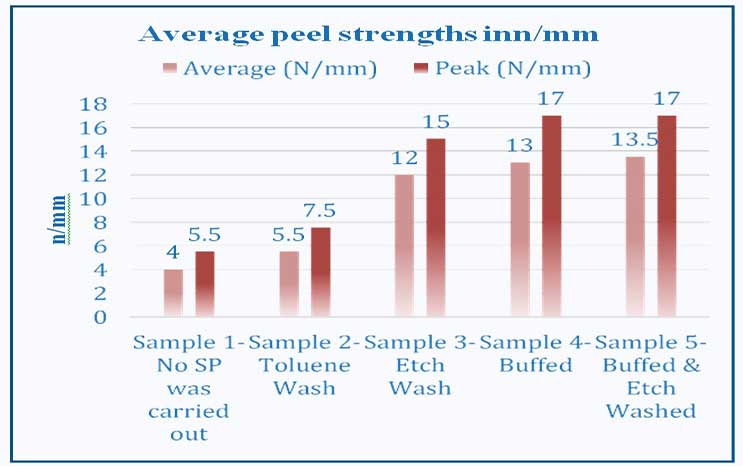

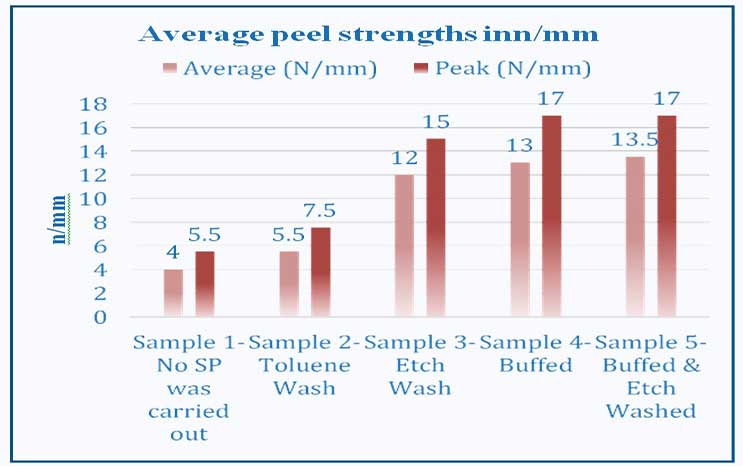

Bonding strength comparison with premium competitor

Bonding strength comparison against different surface preparation