GENERAL

Bulk materials transported from mines to the processing/consuming plants are required to be treated magnetically to remove tramp iron pieces that are carried along with the material, to prevent damages to lhe costly equipments in the downstream process.

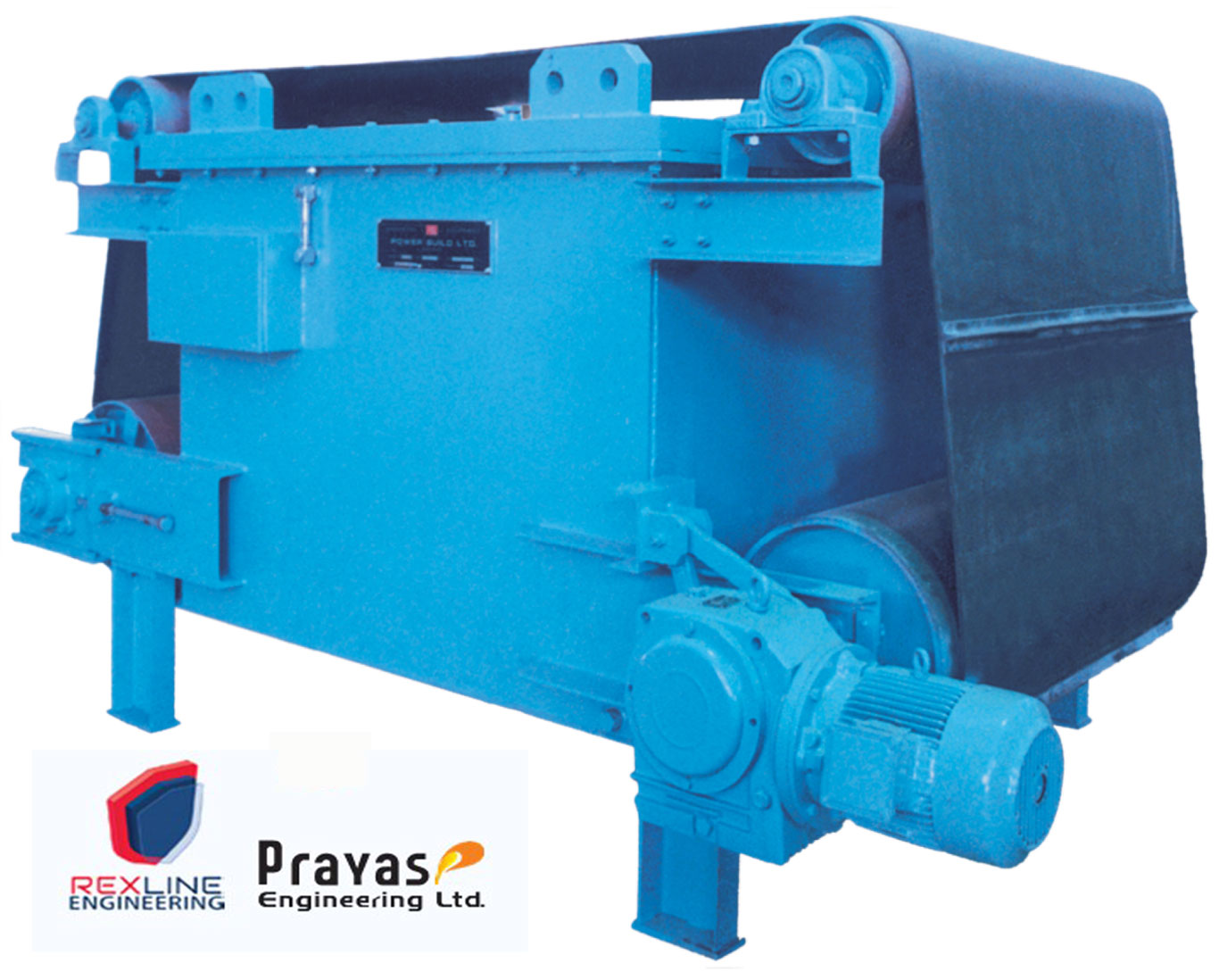

Power Build offers magnetic system to suit every application. Its range of magnets includes Overband Electro Magnetic Separators, Suspended Electro Magnets and Suspended Permanent Magnets. They find application in core sector industries like fertilizer, cement, coal, power generation, chemical, steel plants, etc.

PBL Magnets are designed and manufactured to their latest technological developments in the field of electromagnetism in the highly industrialized countries. Our design meets stringent specifications and application requirements to render long, satisfactory performance. They conform to international standards for both performance and safety.

PBL always endeavoured to upgrade their technology for efficiently servicing their customers and have entered into technical collaboration with world renowned Ets Raoul LENOIR of France for manufacturing magnets to their design.

APPLICATION

Magnetic Separators are primarily used for separation of ferrous material from material transported over a conveyor in different types of applications:

- Protection of downstream processing equipment such as crushers Pulverizers Granulators etc.

- Purification of the product/ingredients for higher quality end product by removing iron pieces from the material in process.

- Reclamation of either the ferrous or non-ferrous material from open hearth and blast furnace slag, incinerator, etc.

In many applications, there can be a combination of protection purification and reclamation operations.

Where the volume of tramp iron is large enough or the tramp iron pieces are encountered frequently and where the access to the magnet is so difficult that manual cleaning is impractical, self-cleaning type Electromagnets are the right choice. These self-cleaning units are provided with aluminium/stainless steel cleats lor continuous auto removal of the tramp iron pIeces.

Permanent Magnets find applicatton where the working height is up to 300mm and the impurities are found accidentally in the bulk handled products.

Electromagnetic Separators are available in manual and self cleaning designs. The manual cleaning (suspended type Separators are ideal for applications where only small amount or occasional pieces of tramp iron are encounlered. They must be periodically turned off in order 10 remove iron accumulation from the face of the magnet.

SALIENT FEATURES

With years of experience, PBL offers rectangular magnets with features that are of critical importance for maximum tramp iron removal. These features are :

- Use of low carbon steel reduces the weight of the magnet and at the same time accommodates higher working flux

- Optimized dimensions and shape of the core and side poles obtain wider, deeper field ensuring large force index at the centre to effect higher lifting

- Use of electrolytic grade aluminium conductors limits heat losses and better

- Use of hiqh quality insulation materials and improved methods impart longer life to the magnet

- Space wound coils design obtains optimum cross-sections of the conductor, efficient heat transfer and low hotspot

- Liberally designed/selected other mechanical components like pulleys, bearing blocks, drive, belt ensure trouble-free operations.

- Oil cooled magnets can be provided for better heat

DETERMINATION OF OPERATING HEIGHT

Operating height requirement should be specified by the user after giving due consideration to various factors. Any over specifying of operating height results into unnecessary high capilal expenditure.

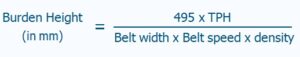

Burden height of the material can be worked out using the following formula :

Operating height should be 75 to 100 mm more than the burden height as calculated above or the maximum lump size, whichever is higher. It should be remembered that for higher lump sizes cross-belt arrangement becomes ineffective.

INSTALLATION

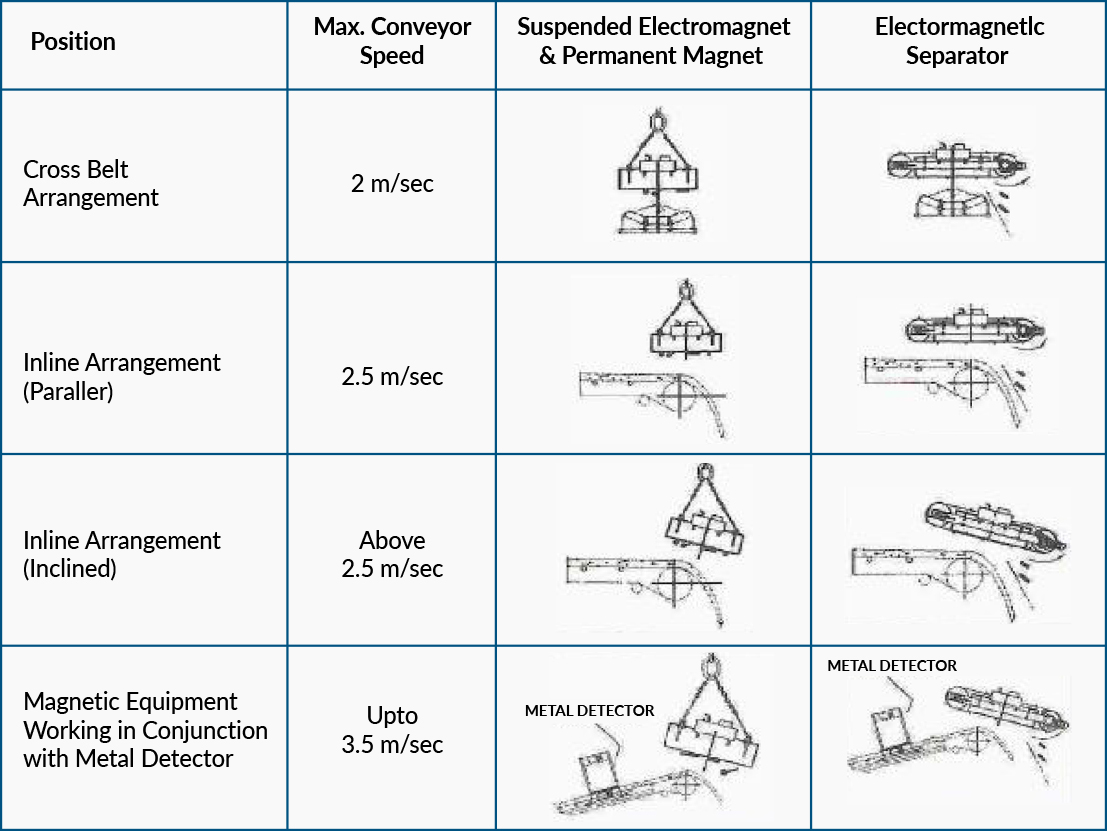

Magnetic Separators can be installed in cross belt or inline arrangements. Preferred installation of the suspended magnet is over the trajectory of the material discharged from the belt oonveyor. If the conveyor is running at 2 M/sec, or more, this is the best way to utilize the full potential of the separator since separation is achieved while the burden depth is “opered-up” In flight. Further, the burden is moving directly towards the magnet face and the momentum of any included tramp iron assists in its separation. At slower eonveyor speed if lhe trajectory of lhe discharged material becomes more clearly vertical, the magnet position must be shifted slightly back over the head pulley.

The cross belt arrangement ol installation of the separator normally presents a more difficult separation problem and surely requires a strong magnet. Cross belt installation is used only when inline arrangement is not possible due to plant layout and as far as possible, to be avoided. For belt speed excessive or 2 M/sec. Cross bek installation is not at all recommended, as higher lump sizes will not allow effective separation and tramp iron pieces with tendency lo be lifted vertically will puncture the separator belt.

Normally magnet is designed for continuous duty and there is considerable power loss due to resistance of the coil (1 R loss). The present trend is to over excite the magnet only when a tramp iron is encountered, while normally the magnet is in under-excited condition. This is achieved by installation of a Metal Detector prior to the magnetic Separator. As ard when the tramp iron is detected, the metal detector sends a signal to the magnetic circuit to increase its magnetic strength temporarily for separation ot the tramp iron piece. This arrangement leads to a lot of saving in energy and at the same time achieving the goal of efficient removal of tramp iron, in many cases by employing a smaller size magnet.

PBL offers magnetic equipments of all types in air cooled and oil cooled designs and can offer ideal and most economic solution to the problems of effective tramp iron separation.

All components located within the zone of active magnetic field should be of non-magnetic material.

SELECTION

Most important features in the selection of the proper size of magnetic separators are burden depth, belt width, suspended position and tramp iron size.

Since other factors may affect the choice of the proper magnet, intelligent engineering practice dictates that each application be individually reviewed by a PBL application engineer before the selection is made. The following information is required to make a proper recommendation :

- Capacity cf the conveyor m tomes per

- Belt

- Belt

- Burden

- Maximum lump

- Size and shape (minimum and maximum) of tramp iron pieces to be

- Troughing

- Bulk density of the

- Arrangement of the magnet, e. cross belt or inline.

- Conveyor

- Ambient

- Available