PULLEY LAGGING

Our Diamond and Ceramic Pulley lagging is the engineered with only the highest wear resistant ceramic tiles and Diamond profiling. Our lagging now comes in roles of 20m and 10m lengths for easy application and to eliminate waste

REXWRAP™ Diamond Pulley Lagging

- REXWRAP™ DIAMOND PULLEY LAGGING is our trademarked high performance 60 Duro Black lagging to give ultimate abrasion resistance in the highest wear areas of a pulley.

- REXWRAP™ is a self cleaning lagging with a large diamond Profile to help with channeling dirt and water away from the pulley.

- REXWRAP™ is available with a CN bonding layer to give excellent adhesion to the Steel Pulley surface.

- REXWRAP™ has outstanding physical properties making it the number one choice for Pulley lagging.

Features & Propertie

| Technical Specifications | |

| Polymer | NR/BR |

| Specific gravity | 1.10 ± 0.05 |

| Hardness | 60 ± 5 Shore A |

| Tensile strength (min) | 20 MPa |

| Elongation at break (min) | 600 % |

| Abrasion resistance (max) | 90 mm³ |

| Temperature Rating | -20°C to +70°C |

Available Dimensions

- 10 x 500 x 20000 mm

- 12 x 500 x 20000 mm

- 15 x 500 x 20000 mm

*REXWRAP™ Laggings can be manufactured and supplied in a wide variety of lengths and thickness. Please contact us with your requirements

REXWRAP™ Diamond Pulley Lagging

REXWRAP™ Ceramic Pulley Lagging

- REXWRAP™ CERAMIC PULLEY LAGGING is our trademarked high performance 60 Duro Black lagging with 92% Alumina ceramic tiles vulcanized into the rubber to give ultimate abrasion resistance in the most high wear areas of a pulley.

- REXWRAP™ is a self cleaning pulley lagging with Radius grooves to conquer the effect of excessive dirt and water build up on the pulley.

- REXWRAP™ Alumina Ceramic tiles have a dimpled profile to help with traction and grip.

- REXWRAP™ is available with a CN bonding layer to give excellent adhesion to the Steel Pulley surface.

- REXWRAP™ has outstanding physical properties making it the number one choice for Pulley lagging.

Available Dimensions

- 12 x 500 x 10000 mm

- 15 x 500 x 10000 mm

*REXWRAP™ Laggings can be manufactured and supplied in a wide variety of lengths and thickness. Please contact us with your requirements

Features & Properties

| Technical Specifications | |

| Polymer | NR/BR |

| Specific gravity | 1.13 ± 0.05 |

| Hardness | 60 ± 5 Shore A |

| Tensile strength (min) | 17 MPa |

| Elongation at break (min) | 405 % |

| Abrasion resistance (max) | 140 mm³ |

| Temperature Rating | -30°C to +60°C |

| Alumina Content | ≥92% |

| Bulk Density | ≥3.63g/cm³ |

| Hardness R45N | Min 77 |

| Flexural Strength | Min 2,447 Kg/cm2 |

| Compressive Strength | Min 19,884 Kg/cm2 |

Comparison Table for Co-Efficient of Friction

| Co-efficient of Friction | Bare Steel Pulley | Rubber Lagging | Ceramic Lagging |

| Dry | 0.25 | 0.50 | 0.75 |

| Wet | 0.15 | 0.35 | 0.55 |

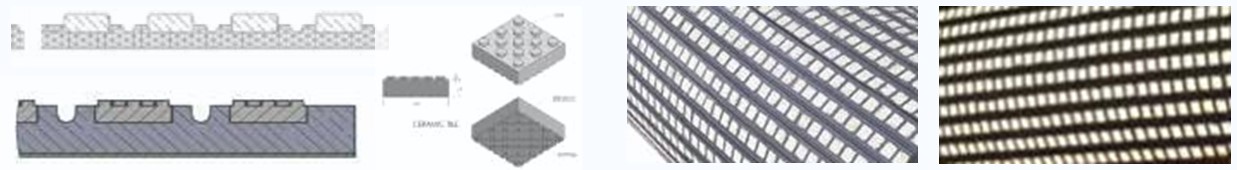

Finger Gripped Engineered Ceramic Pulley Lagging

- Excellent bonding strength from rubber to tiles.

- Back of the tile, the grooves are cut to further improve tile bonding and eliminates tile propping out.

- High tile quality with specified tile specs.

- Square protrusions in the end avoida tracking issues.

- Round knobs are gentle to the belt compared to harsh diamond shaped tiles knobs.

- Radius grooves is an advantage (Allows small pulley diameter and has a self-celaning effect)

- Requires lesser number of sheets cover existing pulley face width

- 10m Roll of 500m width is advantageous, as there is minimal wastage. The sheets available in the market are less than 200m wide.