IMPACT PROTECTION

- Bimetallic wear plates

- Chocky bars and wear buttons

- White iron wear blocks, wear bars

- Microledges

- Bimetallic wear pipes/Liners

- Bucket protectors

- Tungsten carbide wear parts

- Ni-Hard wear parts

- Skid Wear Bar

Laminated Wear Blocks are unique wear resistant materials in that they combine very high wear resistant qualities of white iron (ASTM A532 15/3CrMo, 700BHN – 63HRc) with a weldable & high impact toughness mild steel through a metallurgical bond to create a product that has a exceptional resistance to impact and abrasion.

Ni-Hard material also comes in Hard skirt format with different shapes and sizes depending on the application. The additional chromium content enables the skirts to withstand extended and continuous abrasion in the application.

Features & Properties

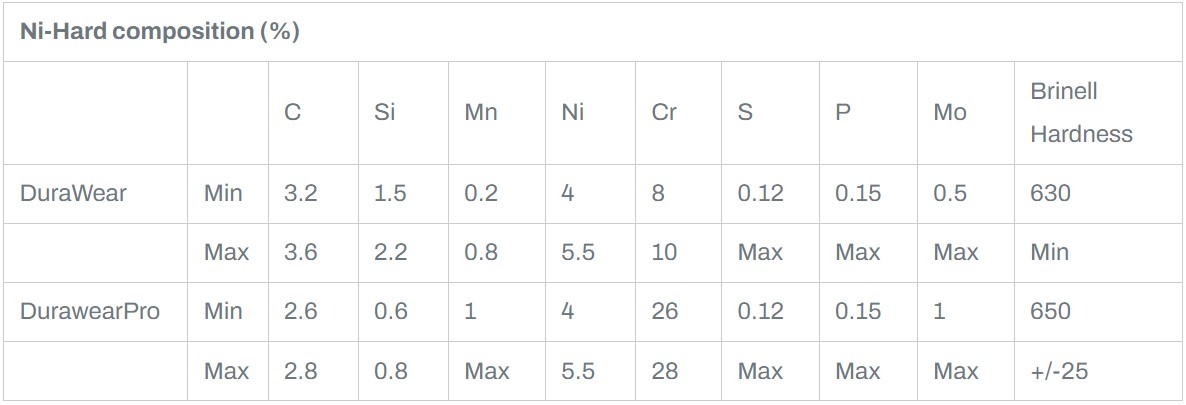

| Ni-Hard composition (%) | ||||||||||

| C | Si | Mn | Ni | Cr | S | P | Mo | Brinell Hardness | ||

| DuraWear | Min | 3.2 | 1.5 | 0.2 | 4 | 8 | 0.12 | 0.15 | 0.5 | 630 |

| Max | 3.6 | 2.2 | 0.8 | 5.5 | 10 | Max | Max | Max | Min | |

| DurawearPro | Min | 2.6 | 0.6 | 1 | 4 | 26 | 0.12 | 0.15 | 1 | 650 |

| Max | 2.8 | 0.8 | Max | 5.5 | 28 | Max | Max | Max | +/-25 | |

- Tensile Strength: 630 Mpa (min)

- TShearing Strength: 250 Mpa (min)

- THardness: 63 HRC