3) Technical Specifications

Process Parameters- Material Properties: Nickel Ore

- Take Up Type: Gravity

- Take Up Mass (Kg): 12000Kgs

- Tonnage (t/h): 500

- Maximum Lump Size(mm): 400 x 550 x 200

- Conveyore Ore: Lumps

- Material Profile: Flat

| MANUFACTURER | REXLINE ENGINEERING |

| MANUFACTURER’S DESCRIPTION/PART NUMBER | EP 1250/4 10 + 3mm 1050 mm width Grade of Cover SCGR Comes with steel breaker top cover |

| MATERIAL NUMBER | NA |

| CLIENT | |

| PURCHASE ORDER | 4506861328 |

| DATE OF PURCHASE | 17/07/2018 |

1) Introduction

Rexline Engineering had supplied Operations with Steel Breaker Belt in July 2018.

This belt was proposed to by Rexline Engineering Technical Team after conducting site audit at request. As part of its re-initiation of operations, all its conveyor systems were audited to identify issues. During the extensive survey of the Site, Rexline Engineering identified issues with the current conveyor belt that it uses against the parameters of operation at site.

Upon approval, Rexline Engineering got its factory to exclusively manufacture and supply this belt for.

Rexline Engineering with its technical expertise in the conveyor industry manufactured the belt to specifications and supplied to on schedule.

2) Case Study

As per Audit conducted by Rexline Engineering on Site, the Site Engineers identified the issues pertaining to the existing conveyor belt. Most sections of the belt are worn out along the length of the belt. Also, there are areas where cuts and gouge have been observed.

Rexline Engineering has identified various factors that led to the belt being cut and gouge. The Rollers used on the conveyor system was way past its service life and required urgent replacements. This led to the belt not being conveyed as required and tracking of the belt.

The Belt Currently in place was not rated for Super Cut and Gouge Resistance. Furthermore, the Belt was only rated for 800/4 Ply Rating with only Fabric Ply as its setup

Rexline Engineering Proposed a SCGR Belt with Steel Breaker along with Higher rating catering to existing conveying tonnage rates.

Also, Rexline Engineering supplied the splice kit necessary on site for splicing of the belt.

Super Cut and Gouge Resistance (SCGR) delivers superior resistance to heavy impacts, abrasion and gouging. Super Cut and Gouge Resistance (SCGR) rubber cover compound provides high end performance in applications where increased resistance to heavy impacts, abrasion and gouging is required in Nickel Operations.

Benefits of High Tensile engineered reinforcement on the top cover:

The Super Cut and Gouge Resistance (SCGR) Belt that we offered is equipped with High Tensile engineered reinforcement on the top cover to provide efficient protection. This High Tensile engineered reinforcement on the top cover provides extra impact and rip protection for the belt and potentially allow smaller pulley diameters, serving as the basis for a longer service life and a lower risk of severe damage.

Technical Data Sheet

| Item | Description | Unit | Specification |

| 1 | Dimensions | ||

| 1.1 | Width of belt | mm | +/-1% |

| 1.2 | Tolerance in belt length | m | +/-2.5% |

| 1.3 | Belt edge | cut | |

| 1.4 | Total thickness | mm | 21.1+/-0.5 |

| 1.5 | Cover thickness | ||

| 1.5.1 | Top cover | mm | 10+/-0.5 |

| 1.5.2 | Bottom cover | mm | 3+/-0.5 |

| 1.6 | Belt weight | kg/m | ~28.14 |

| 2 | Rubber cover | ||

| 2.1 | Specific gravity | g/cm3 | 1.15+/-0.05 |

| 2.2 | Tensile strength | n/mm2 | min.18 |

| 2.3 | Ultimate elongation | % | Min.400 |

| 2.4 | Tensile strength after 70° C x 168h | n/mm2 | Min.200 |

| 2.5 | Ultimate elongation after aging 70° C x 168h | % | Min.200 |

| 2.7 | Abrasion resistance | mm3 | Max.90 |

| 2.8 | Hardness | shore A | 65+/-5 |

| 2.9a | Tearing resistance | n/mm | Min.12 |

| 2.9b | Ozone resistance | 69h 50pphm | No crack |

| 3 | Adhesion | ||

| 3.1 | Top cover to ply | n//mm | 7 |

| 3.2 | Bottom cover to ply | n/mm | 7 |

| 3.3 | Ply to ply | n/mm | 7 |

| 4 | Full belt elongation | ||

| 4.1 | At 10% reference load | % | Max.2.5 |

| 4.2 | At breaking | % | Min.14 |

| 5 | Trough ability at 40° troughed idlers | 0.16 | 0.16 |

| 6 | Tracking | mm | 60 |

| 7 | Full belt tensile strength | n/mm | min.1250 |

| 8 | Steel breaker | Top | |

| 8.1 | Cord diameter | mm | 1 |

| 8.2 | Cord pitch | mm | 10 |

Testing Conducted

- Test Type: Thickness of belt

- Test Standard: AS 1334.2 Determination of thickness of belting and rubber covers across the width

- Required properties: Meet the requirements of AS12-2000 clause 5.3 Tolerance on thickness of belting across width

- Sample ID: AWBH18157

- Note 1:

- Discussion: Pass

| Property | AWBH18157 | Minimum requirements AS 1332-2000 |

| Minimum thickness of belt (mm) | 21.1 | |

| Maximum thickness of belt (mm) | 22.1 | |

| Maximum difference between any two measurement of thickness of belt (%) | 1.0 | AS 1332-2000 CI 5.3 Thickness of belt >10 variation 1.1 max variation |

- Test Type: Tensile strength and elongation of full thickness belt

- Test Type: AS 134.4 Determination of full thickness tensile strength and elongation of conveyor belting

- Required Properties:

- Meet the requirements of AS 1332-2000 clause 6.1 tensile strength of belt carcass

- Meet the requirements of AS 1332-2000 clause 6.2 elongation of belting

- Sample ID: AWBH1857

- Note 1:

- Discussion: Pass

| Property | AWBH18157 | Minimum requirements AS 12-2000 |

| Average longitudinal tensile (kn/m) | 1320 | AS 1322-2000 CI 6.1 1250 kn/m minimum |

| Longitudinal elongation at 10% of the tensile strength as appropriate to the | 2.0 | AS 132-2000 CI 6.2 4% max elongation |

| Longitudinal elongation at breakpoint (%) | 22.1 | AS 132-2000 CI 6.2 10% minimum |

| Average transverse tensile strength (kn/m) | 408 | AS 1332-200CI 6.2 Specified by purchaser |

| Transvers elongation at break point (%) | 26.7 | AS 1332-2000 CI 6.2 10% Minium |

- Test Type: Cover and ply adhesion

- Test Standard: AS 1334.7- Determination of ply adhesion of belting- longitudinal direction

- Required Properties: Meet the requirements of As 1332-2000 clause 6.6 cover and ply adhesion.

- Sample ID: AWBH18157

- Note 1:

- Discussion: pass

| Property | AWBH18157 | Minimum requirements AS 132-2000 |

| Ply adhesion Carry-Ply 1-Top Cover (kn/m) | 9.8 | AS 132 CL 6.6 Cover to ply 4.3 kn/m mean |

| Ply adhesion Carry-Ply 2 (kn/m) | 9.0 | AS 132 CL 6.6 Adjacent plies 5.3 kn/m mean |

| Ply adhesion Carry-Ply 3 (kn/m) | 9.1 | |

| Ply adhesion Carry-Ply 4 (kn/m) | 8.7 | |

| Ply Adhesion Ply 4- Bottom cover (kn/m) | 6.0 | AS 132 CL 6.6 Cover to ply 4.3 kn/m mean |

4) Project Benefits Review

| PARAMETER | BENEFITS |

| SERVICE LIFE |

|

| COST | Replacement and Maintenance costs of these belts was reduced by 40% considering for a year’s worth of service life. |

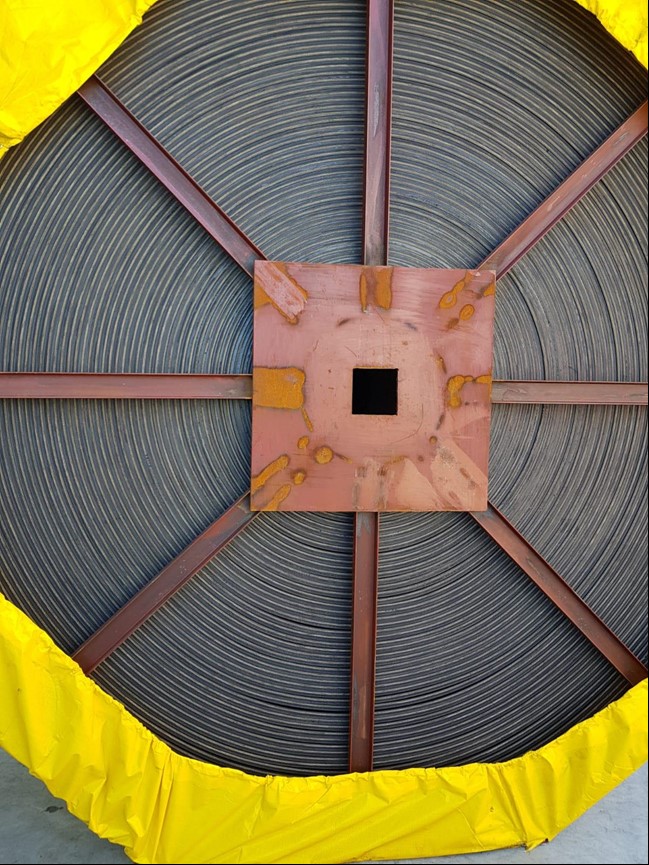

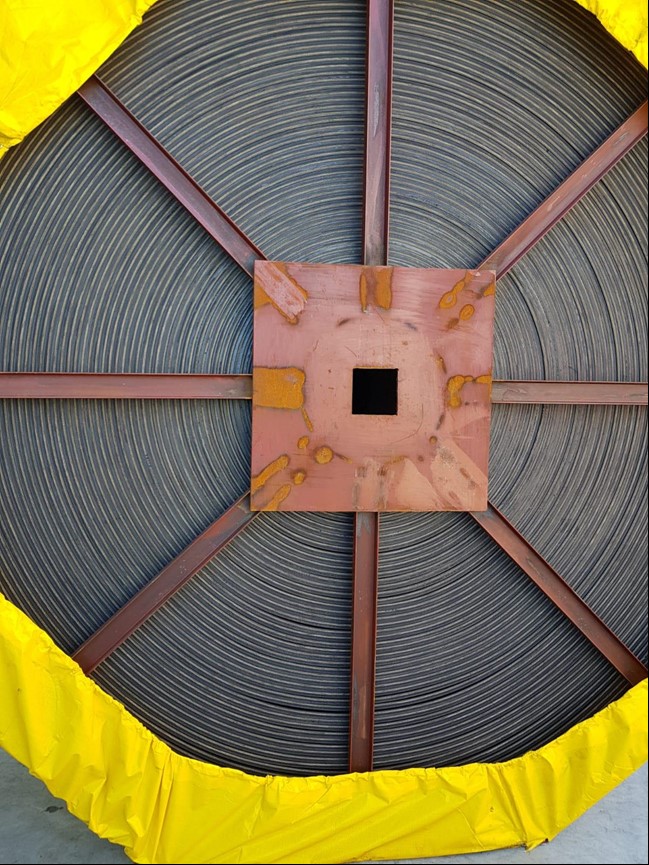

Photos