Alumina Tiles And Composite Liners

Composite Ceramic Liners & Mats

REXLINE™ ceramic wear liners range include composite ceramic liners or Steel backed and studded as per requirements. We also have a range of molded ceramic in rubber with CN backing. The liners can be customized depending on the application.

Ceramic Liners Tile Format

| Steel Backed Ceramic Liners | ||||

| Tile Thickness | Tile size in mm | Rubber in mm | Steel in mm | Liner Sizes (mm) |

| 32mm | 20 | 6 | 6 | 300/150 |

| 300/300 | ||||

| 300/450 | ||||

| 300/600 | ||||

| 450/450 | ||||

| 64mm | 50 | 8 | 6 | 300/150 |

| 300/300 | ||||

| 300/450 | ||||

| 300/600 | ||||

| 450/450 | ||||

| 37mm | 25 | 6 | 6 | 300/150 |

| 300/300 | ||||

| 300/450 | ||||

| 300/600 | ||||

| 450/450 | ||||

| 69mm | 55 | 8 | 6 | 300/150 |

| 300/300 | ||||

| 300/450 | ||||

| 300/600 | ||||

| 450/450 | ||||

Composite Ceramic Data Sheet

| Technical Data of the Ceramics | |||

| Description | 92% Ceramics | 95% Ceramics | ZTA |

| Alumina Content | 92% | 95% | – |

| Density (g/cm³) | 3.61 | 3.62 | 4.1 |

| Rockwell Hardness (HRA) | 85 | 88 | 90 |

| Vickers’ Hardness (HV10) | 1200 | 1350 | 1400 |

| Fracture Toughness (KIC or MPa.√m) | 3.6 | 4.1 | 5.5 |

| Compressive Strength (MPa) | 2000 | 2281 | 2924 |

| Wear Volume (cm³) | 0.02 | 0.017 | 0.009 |

Technical Data of the Rubber

| Items | Index |

| Elongation | ≥ 450% |

| Tensile Strength | ≥ 180 MPa |

| Break Extension | ≥ 500% |

| Shore Hardness | 55 – 65 HA |

| Tear Strength | ≥ 70 KN/M |

| Break Permanent Deformation | ≤ 24% |

| Rubber and Ceramic Adhesion Force | ≥ 3.0 MPa |

| (Shearing Stress) | |

| Temperature Resistance | ≤ 100˚ C |

| Rubber Aging Life | ≥ 8 years |

| Gap Between Tile | 0.8 – 2.0 mm |

| Rubber Edge | 1.5 – 2.0 mm |

Technical Specifications

| Description | 92% Ceramics | 95% Ceramics | ZTA |

| Alumina Content | 92% | 95% | – |

| Density (g/cm³) | 3.61 | 3.62 | 4.1 |

| Rockwell Hardness (HRA) | 85 | 88 | 90 |

| Vickers Hardness (HV10) | 1200 | 1350 | 1400 |

| Fracture Toughness, Kic (Mpa.m½) | 3.6 | 4.1 | 5.5 |

| Compressive Strength (MPa) | 2000 | 2281 | 2924 |

| Wear Volume (cm³) | 0.02 | 0.017 | 0.009 |

Technical Data Sheet Of REXLINE™ Ceramic Liner

| Technical Data of the Rubber | |

| Items | Index |

| Elongation | ≥ 450% |

| Tensile Strength | ≥ 180 MPa |

| Break Extension | ≥ 500% |

| Shore Hardness | 55 – 65 HA |

| Tear Strength | ≥ 70 KN/M |

| Break Permanent Deformation | ≤ 24% |

| Rubber and Ceramic Adhesion Force | ≥ 3.0 MPa |

| (Shearing Stress) | |

| Temperature Resistance | ≤ 100˚ C |

| Rubber Aging Life | ≥ 8 years |

| Gap Between Tile | 0.8 – 2.0 mm |

| Rubber Edge | 1.5 – 2.0 mm |

Technical Data of the Ceramics

| Description | 92% Ceramics | 95% Ceramics | ZTA |

| Alumina Content | 92% | 95% | – |

| Density (g/cm³) | 3.61 | 3.62 | 4.1 |

| Rockwell Hardness (HRA) | 85 | 88 | 90 |

| Vickers’ Hardness (HV10) | 1200 | 1350 | 1400 |

| Fracture Toughness (KIC or MPa.√m) | 3.6 | 4.1 | 5.5 |

| Compressive Strength (MPa) | 2000 | 2281 | 2924 |

| Wear Volume (cm³) | 0.02 | 0.017 | 0.009 |

| INDUSTRY | PRODUCT | ASSET | LOCATION | INSTALLED | MATERIAL SIZE | THROUGHPUT | ROI |

|---|---|---|---|---|---|---|---|

| Nickel Mine | 95% Zirconia Toughened Alumina Tiles | Chute 503 | Western Australia | August 2016 | ≤600mm material passes through the underflow of the primary crusher and through to the primary stockpile | TBA | Replacing Overlay Liners with Ceramic Composite Liners |

Technical Data Sheet Of REXLINE™ Ceramic Liner

Technical Data of the Rubber | |

| Items | Index |

| Elongation | ≥ 450% |

| Tensile Strength | ≥ 180 MPa |

| Break Extension | ≥ 500% |

| Shore Hardness | 55 – 65 HA |

| Tear Strength | ≥ 70 KN/M |

| Break Permanent Deformation | ≤ 24% |

| Rubber and Ceramic Adhesion Force | ≥ 3.0 MPa |

| (Shearing Stress) | |

| Temperature Resistance | ≤ 100˚ C |

| Rubber Aging Life | ≥ 8 years |

| Gap Between Tile | 0.8 – 2.0 mm |

| Rubber Edge | 1.5 – 2.0 mm |

Technical Data of the Ceramics | |||

| Description | 92% Ceramics | 95% Ceramics | ZTA |

| Alumina Content | 92% | 95% | – |

| Density (g/cm³) | 3.61 | 3.62 | 4.1 |

| Rockwell Hardness (HRA) | 85 | 88 | 90 |

| Vickers’ Hardness (HV10) | 1200 | 1350 | 1400 |

| Fracture Toughness (KIC or MPa.√m) | 3.6 | 4.1 | 5.5 |

| Compressive Strength (MPa) | 2000 | 2281 | 2924 |

| Wear Volume (cm³) | 0.02 | 0.017 | 0.009 |

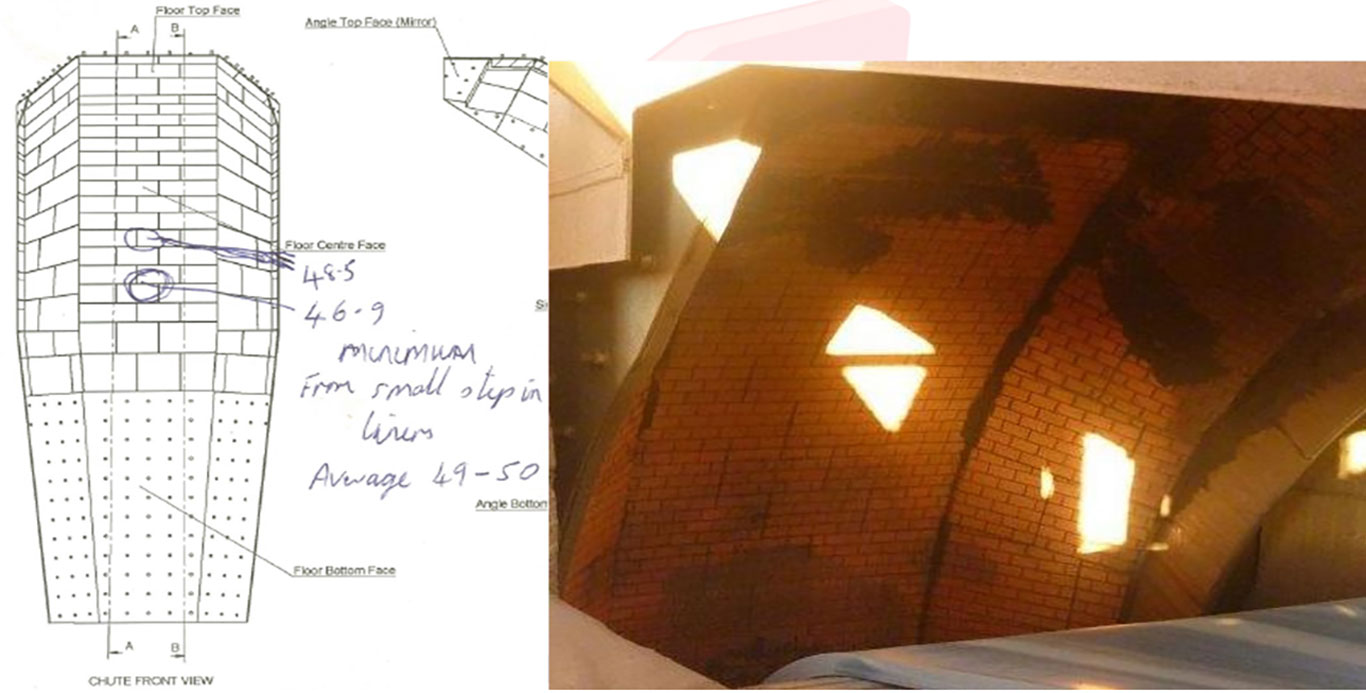

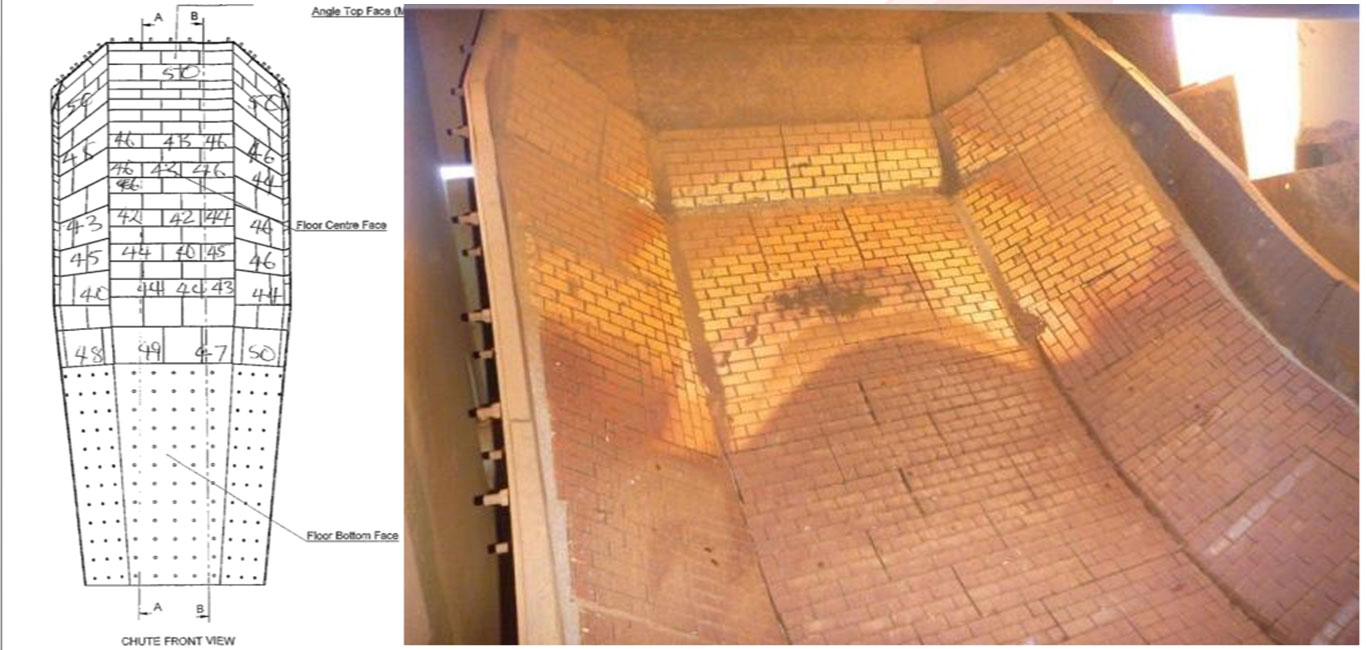

Project Overview

| INDUSTRY | PRODUCT | ASSET | LOCATION | INSTALLED | MATERIAL SIZE | THROUGHPUT | ROI |

|---|---|---|---|---|---|---|---|

| Nickel Mine | 95% Zirconia Toughened Alumina Tiles | Chute 503 | Western Australia | August 2016 | ≤600mm material passes through the underflow of the primary crusher and through to the primary stockpile | TBA | Replacing Overlay Liners with Ceramic Composite Liners |

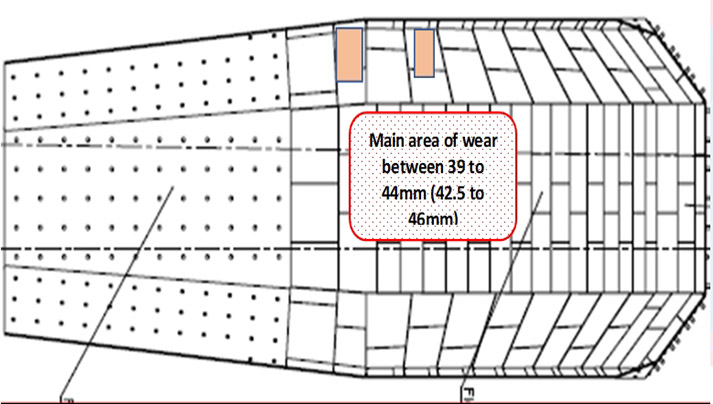

Location of Installation

Impact plate Chute 503 – 02

History of Previous Liner

Previously installed Weld Overlay Liners were experiencing irregular and frequent wear requiring in-site repairs and change out of liners.

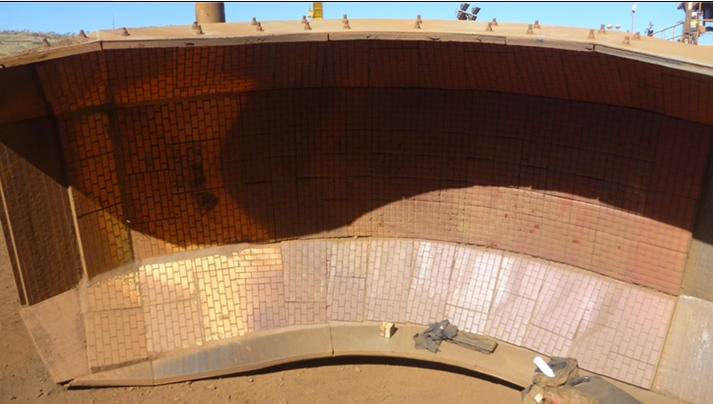

Refurbishment

During refurbishment, 32mm Weld Overlay Liners were kept in the non-impact zone while REXLINE™ ZTA Ceramic Liners were installed in the main impact areas

Update – September 2016

Following the first inspection after 3 months the most wear measured was 1.5mm in the centre impact zone.

Update – April 2017

Following the second inspection after 9 months the most wear measured was 8-10mm in the centre impact zone.

Summary & Service Life