Vehicle Restraints

This equipment holds a trailer’s rear impact guard to secure it from vehicle creep or unscheduled departures. This prevents forklift fall-through, which is one of the most dangerous types of accidents occurring at warehouse loading docks.

Vehicle restraints are more preferred than wheel chocks since they are safer and not placed manually like chocks, which are susceptible to incorrect application and human errors.

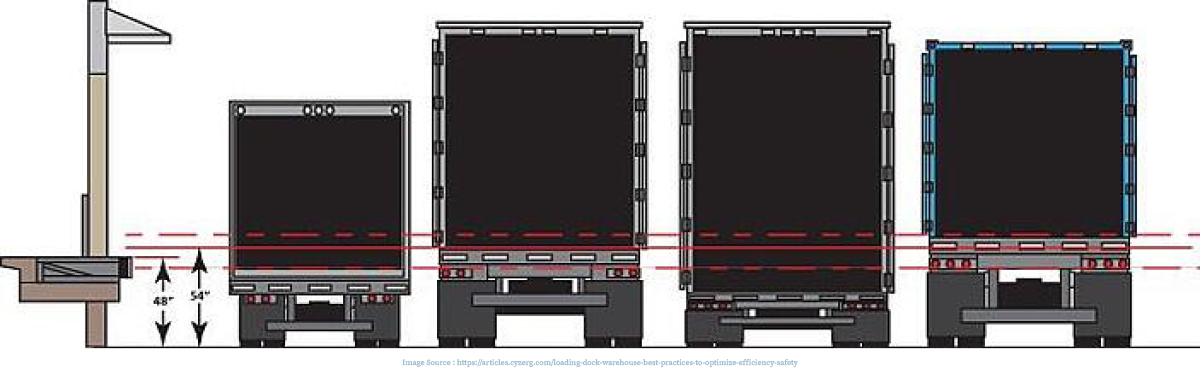

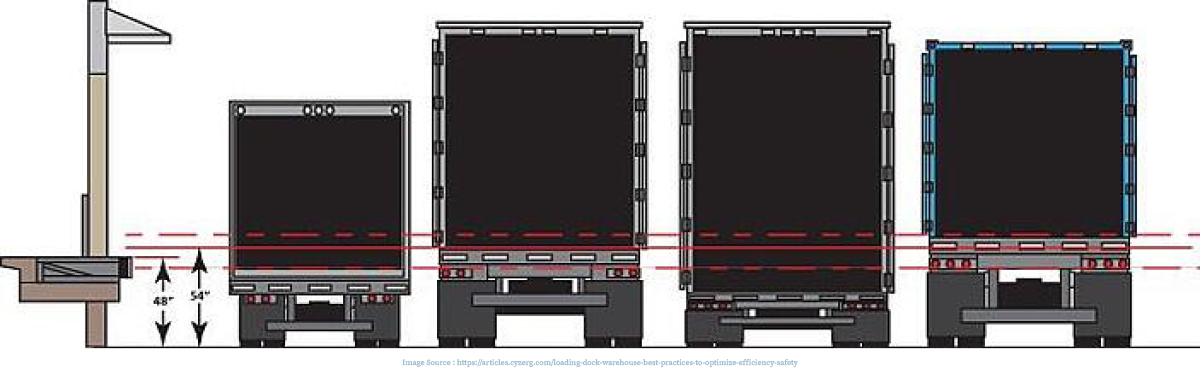

Hydraulic Dock Levelers

Dock levelers are equipment used to accommodate different trailer floor heights. Hydraulic dock levelers, specifically, are more recommended since it operates with a push of a button and doesn’t require workers to bend down in an awkward position that is susceptible to injury – just like mechanical levelers.

Additionally, hydraulic dock levelers are cost-effective in the long run since they require less maintenance than mechanical levelers.

Conveyors

Conveyors are material-handling equipment that facilitate the transportation of cargo from one place to another. For loading dock operations, warehouse conveyor systems ease the movement of cargo from the truck to the staging area, greatly improving warehouse efficiency and safety because of less human intervention.

Be Aware and Learn the Possible Dangers

In the industrial sector, 25% of accidents occur at the warehouse loading docks. And, as per OSHA, 71 accidents occurred at loading docks from 2017 to 2019, with 19 of them being fatal.

Proper Ventilation & Fans

Loading docks involve the use of machines and vehicles that produce hazardous fumes to workers. Without proper ventilation, workers can inhale dangerous chemicals and run into potential health risks, which could cost your company a substantial amount.

In addition to fumes, warehouse loading dock operations involve loading and unloading cargo to and from hot trailers. This can cause dehydration and discomfort, which can decrease productivity or worse, lead to accidents.

Loading dock operations require efficient management, as it is responsible for the inflow and outflow of cargo that greatly influences warehouse productivity. Additionally, according to OSHA, it involves 25% of accidents in the industrial sector, so proper safety measures should be in place. Following the four best practices mentioned above can help you process more cargo and increase efficiency, but also, help mitigate accidents.