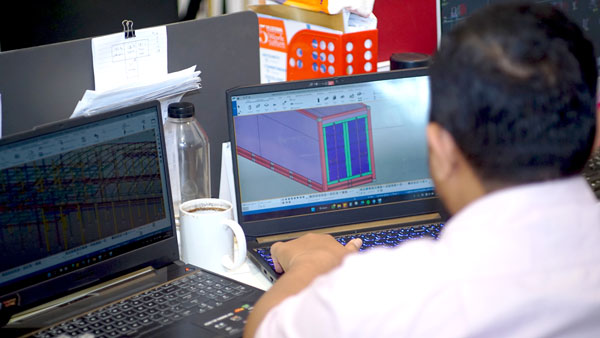

Rexline follows Indonesian SNI and global codes ACI, AISC, API, ASTM, ASME, IEC; licensed drawings with AutoCAD, Tekla, STAAD Pro, SolidWorks, SAP2000.

Rexline designs land and marine foundations, using STAAD Pro, Tekla; detailing piles, slabs; seismic inputs; BOQs, drawings; compliant with SNI, ACI.

Rexline develops crushing plants with conveyors, hoppers, tanks; prepares P&ID, GA, fabrication drawings; stress analysis, automation, equipment lists, and plans.

Rexline designs LV/MV electrical systems, panels, cable layouts, single-line diagrams, SCADA/PLC integration, earthing, lightning, power studies, instrumentation, and control specifications.

Rexline’s Lamongan facility uses CNC plasma, laser, bending, rolling, lathe, milling, shearing machines; 210 staff in fabrication, QC, logistics; two-shift operations, sandblasting, painting, in-house rollers/pulleys.

Rexline operates a 23,000 sqm Lamongan yard, fabricating steel, tanks, conveyors, trestles; ASME-certified welders, ISO 3834 practices; modular jetty/plant structures with pre-assembly and trial fitting.

Rexline conducts inspections, UT, RT, MPT, hydrostatic tests, coating and DFT checks, with full ITPs and Quality Dossiers for fabricated tanks, vessels, and structures.

Rexline manages steel erection, equipment alignment, bolting, coupling, panel mounting, cabling, testing, commissioning, startup checks, and HSE site audits.

Rexline handles sea/land freight, break-bulk, containers, export packing, customs clearance, delivery tracking, and heavy-lift cargo coordination.

Rexline follows SNI and global codes ACI, AISC, API, ASTM, ASME, IEC, with permit drawings, AutoCAD, Tekla, STAAD, SolidWorks, and SAP2000.

Rexline builds pile jetties for 5k–50k DWT ships, installs concrete or steel piles, decks, dolphins, trestles, coatings, cargo yards, fencing, conveyors, drainage, and admin.

Rexline provides rotary and vibrating screens, magnetic separators, feeders, crushers 100–2000 TPH, sandblasting, painting, pulleys, mobile units, dust and safety.

Rexline builds overland conveyors to barge jetties, with transfer towers, galleries, stackers, trestles, safety sensors, dust chutes, loading heads, pulleys, and drives.

Rexline builds pile jetties for 5k–50k DWT ships, installs concrete or steel piles, decks, dolphins, trestles, coatings, cargo yards, fencing, conveyors, drainage, and admin.

Rexline builds LGSF staff housing 60–180 sqm, with steel frames, foam walls, quick panels, insulation, soundproofing, solar systems, flexible layouts, and dorms.

Rexline delivers turnkey camps 50–500 staff, with prefab dorms, offices, kitchens, MEP services, solar or diesel backup, water, sewage, fire safety, fencing, and CCTV.

Rexline designs 30T–100T haul roads with grubbing, cut-fill, compaction, stone base, geotextile, culverts, drains, signage, lighting, slope and gradient control.

Rexline performs SPT, CPT, and soil sampling, conducts GPS and sonar surveys, tests soil resistivity, and prepares geotechnical reports for foundations.

Rexline designs generator rooms with cabling and sync panels, installs transformers, routes cables, builds earthing, lightning, surge systems, and solar-diesel backup.

Rexline applies HSE per ISO 45001 and local rules, with risk checks, toolbox talks, PTW, LOTO, emergency response, dossiers, ITPs, audits, and certifications.