1 Introduction

Rexline Engineering supplied Operations with Petrol Resistant Belt in September 2018.

This belt is specially designed to convey corrosive material that is alkali or acidic in nature as this belt is chemical resistant, crude oil resistant, and petrol resistant.

Upon approval, Rexline Engineering got its factory to exclusively manufacture and supply this belt for

Rexline Engineering with its technical expertise in the conveyor industry manufactured the belt to specifications and supplied it on schedule.

2 Case Study

At request of Oil Resistant belt complying to Australian Standards, Rexline Engineering was awarded the contract for supply of this specially designed belt.

The Synthetic fabric of the belt is impervious to oil, turps, and moisture. The top and bottom covers are made of oil resistant black rubber so that they retain their shape, hardness, and surface characteristics, also available OHR (Oil & Heat Resistant) Belt.

Oil-resistant conveyor belts are immensely used for conveying the components & parts coated with machine oil, heavy-oil treated coal in cooking plants & electric power generating plants. These oil-resistant belts are also used for carrying foods and other oily materials containing non-polar organic solvents & fuel.

These carefully designed oil-resistant belts are not affected by paraffin oil, naphthene-based oils, petrol, animal or vegetable fats, etc.

Our oil-resistant belts are in line with international quality standards and hence most sought-after in the global markets.

3 Technical Specifications

- This Belt is manufactured from high quality materials on state of art manufacturing facility

Improved high performance textile carcasses, for low stretch and improved tracking - High Quality Synthetic Covers for high abrasion and oil resistance

- Sealed Underside construction for hygiene and long service life

- High adhesion levels, manufactured to exacting tolerances ensure consistent belt performance.

| 2000mm wide EM 20/4 00+15 / 5.0 | |||

| Item | Description | Unit | Specs |

| 1 | Min Pulley Diameter | mm | 150 |

| 2 | Thickness | mm | 5.00 |

| 3 | Weight | Kg/m2 | 5.50 |

| 4 | Carcass | – | Monofilament |

| 5 | Electro Static Properties | – | Non Anti – Static |

| 6 | Temp | C | -10 to +80 |

| 7 | Belt Strength | N/mm at 1% Stretch | 20 |

| 8 | Conveying Surface | – | PVC Smooth |

| 9 | Drive Surface | – | PVC Impregnated |

| 10 | Stock Width | mm | 2000 |

| 11 | Prod Width | mm | 3000 |

4 Project Benefits Review

| PARAMETER | BENEFITS |

| SERVICE LIFE | The beltis currently in operation since it has been installed in September2018. This belt is currently in operation is due for replacement in March. Service Life: 6 Months |

| COST | Replacement and Maintenance costs of these belts was reduced by 10% considering for a year’s worth of service life. |

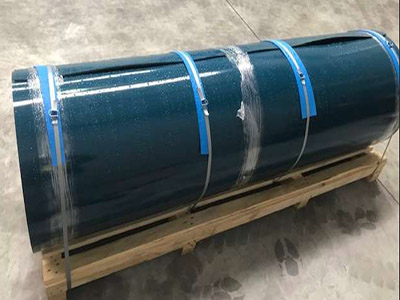

5 Photos

Petrol Resistant Conveyor Belt Supplied