Chromium Carbide Overlay Wear Bands

PROJECT DETAILS

| MANUFACTURER | REXLINE ENGINEERING |

| MANUFACTURER’S DESCRIPTION/PART NUMBER | Chromium Carbide Overlay Wear Bands |

| MATERIAL NUMBER | NA |

| CLIENT | |

| PURCHASE ORDER | 166581 |

| DATE OF PURCHASE | 28/02/2018 |

1 Introduction

Rexline Engineering Department worked in close relation with to service its client to supply high wear resistant and medium impact liner to protect their high value capital equipment- The Sizing Crusher.

Rexline Engineering in consultation with its engineering department and end user, supplied its High Chromium Ultraclad Steel Liner manufactured at state-of-the-art Submerged Arc Welding Factory.

2 Case Study

Engineering as part of its refurbishment business for its client, was in dire need for a high wear resistant material for the sizing crusher.

The drum inside the crusher wears out pretty quickly hence resulting in breakdowns and high maintenance intervals. Considering these equipment’s are highly performance driven and tonnage achieved is of importance, a breakdown is last thing needed.

Rexline Engineering has developed its Chromium Carbide Steel Liner over years of reengineering and tests conducted over its chemical composition based on client requirements. Rexline Engineering engineers suggested this product based on similar past applications.

Considering the Shape and manufacturability, these liners were welded on submerged arc welding station and were curved to suit the drum profile. As part of its services, Rexline Engineering conducted QA/QC and Dimensional Checks to ensure the product is top quality and can be installed on the crusher with ease and each liner can be interchanged.

| Chemical Composition of Wear Resistant Material Deposition | |||||

| Size | 12 on 12 | Grade | D80 | Standard | AS/NZS 2576: 2005 |

| Description | C | Cr | Mn | Si | Fe |

| Requirement | 3.00 – 5.00 | 34.0 – 45.0 | 0.50 -2.50 | 0.50 – 1.50 | |

| Test Result | 4.12 | 39.4 | 1.02 | 0.81 | Bal |

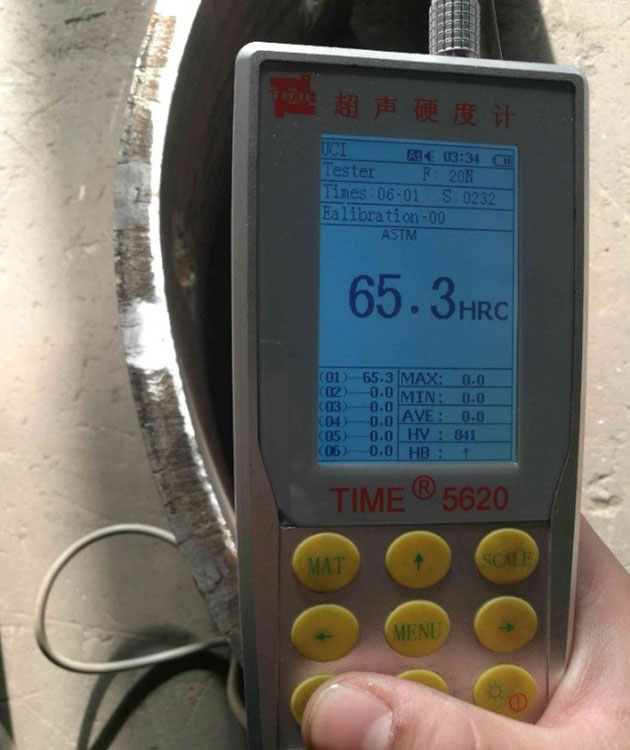

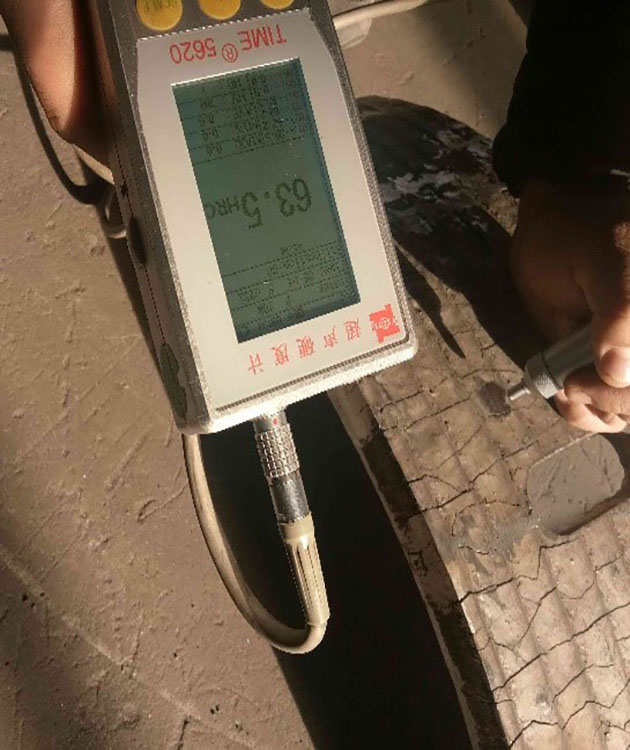

| Hardness of Deposited Metal | 58 – 63 | ||||

| Recorded Hardness | 62.2 | ||||

| PARAMETER | BENEFITS |

| SERVICE LIFE | The steel liners were installed in March 2018 in the Crusher. It was replaced in November 2018. Service Life: 8 Months.The Service Life Increased by 125%. |

| COST | Replacement and Maintenance costs of these belts was reduced by 35% considering for a year’s worth of service life. |

Photos

VISUAL CHECKS

HARDNESS CHECKS

DIMENSIONAL CHECKS